More power for Danfoss: AI-assisted automatic warehouse

Sector: Heating and cooling technology

Company: 27,000 employees spread across 100 countries. 71 production locations in more than 20 countries.

Challenge: Approx. 2,000 articles on roughly 8,800 pallets.

Solution: Automatic warehouse in combination with three automated industrial trucks from series production (MX-X and EXV), including the installation of all system components. iGo insights cloud-based solution for system optimisation. Innovative, remotebased proximity warning system (ELOshield) protects pedestrians from oncoming trucks.

For the new Danfoss Power Electronics A/S production warehouse in the Danish town of Tinglev, STILL delivered a perfectly conceived combination of three automated industrial trucks from series production (MX-X and EXV), which included installing all the system components. Systems were optimised via the cloud using the smart tool iGo insights and thanks to the proximity warning system, pedestrians are optimally protected from oncoming trucks.

Well equipped to face the future

After increasing its range of frequency converters for electric motor controllers, Danfoss found that its manual production warehouses in Gråsten and Kliplev were reaching the limits of their capacity. According to Martin Rosengreen Jessen, Danfoss Production Supervisor at the new Tinglev warehouse, “Our goal was to increase our capacity by merging the warehouses with an automatic warehousing system. In order to give ourselves the flexibility we need for the future, we opted for STILL’s iGo system with automatic industrial trucks. And thanks to the full-service lease agreement, we can keep a firm overview of the warehousing costs over the next six years.”

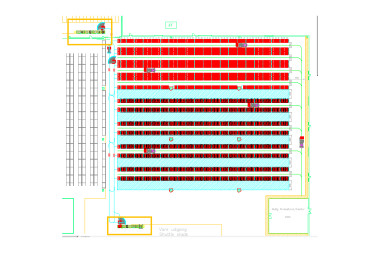

In the automatic warehouse, the interfaces between the pallet conveyor systems and the AGVs (Automated Guided Vehicles) are located in both the incoming and outgoing goods areas. According to the ABC analysis, around 2,000 different articles are stored on roughly 8,800 pallets. The warehouse is currently split into two areas; on one side there is a fully automated very narrow-aisle warehouse and on the other a semi-automated warehouse area. The narrow aisles for the MX-X alternate with wider aisles for manual order picking from the bottom two rows of the seven-metre-high racks.

Efficient warehousing

Thanks to the new automatic warehouse, daily deliveries by truck to the production hall in nearby Gråsten can take place every three hours, five days a week. “The time savings are phenomenal. This is thanks in part to the centralised warehousing system, but the main factor is the automation of our production warehouse, which we operate around the clock,” says Martin Jessen. With production activities set to focus on new product series, the requirements at the Tinglev warehouse will look different in the future too. Articles will be delivered on full pallets, before being shipped out in the same way. As Henrik Rosendahl Laursen, Warehouse & Distribution Consultant at Danfoss Distribution Services, explains: “In the near future, less of our order picking will be done manually as we shift more towards automation. Our new warehouse is perfectly prepared for this, since we took scalability into account when meticulously planning the new concept. In the wide aisles where we still pack production parts onto pallets manually for now, we will be able to install additional racks for automatic order picking.” Ole Lambrecht, Project Manager for STILL DANMARK in Kolding, stresses the benefits of scalability at the warehouse: “Additional AGVs will allow us to respond quickly and flexibly to higher capacity demands in the future. For special applications, such as when switching to automatic warehouse operation, we will still be able to operate our AGVs manually.”

Demand-driven automation

STILL series-produced industrial trucks are equipped with the iGo systems automation kit for consistent automation of the material flow. Identical components, controllers and interfaces come together to create a high-performance AGV in no time at all. The following components are installed:

- laser scanner for truck navigation

- automation box for the steering unit – receives driving instructions from the control system

- indicator lights – indicates truck’s direction of travel

- safety laser scanner for 360-degree truck monitoring and personal protection

- user interface with screen or touchscreen

- emergency stop button on lift mast and screen.

An appropriate sensor is installed on all AGV forks to ensure precise pallet detection. Meanwhile, a carefully selected combination of navigation technologies ensures that the trucks can move around safely and autonomously. The MX-X trucks are therefore operated inductively in the aisles. In addition, all AGVs navigate using laser scanners, which constantly measure the distance to reflectors installed in the warehouse.

Meticulous planning and design

A fully automated material flow with a range of automated series-production trucks is what sets STILL’s iGo systems apart. “By selecting technologies that work in perfect harmony with one another, we have been able to analyse, plan and implement a demand-driven automation concept for Danfoss. The main factors in the decision to award the contract to STILL were short response times compared to the market competitors, both in terms of preparing the design and quote, and also in implementing the automation,” says Ole Lambrecht. Following initial discussions in September 2018 and the awarding of the contract in February 2019, the equipment was installed between January and May 2020. Henrik Laursen adds that the floor plan for the first draft of the warehouse included 50 crossover points between AGVs and pedestrians. Thanks to optimisation during the careful planning stage, these were reduced to just five crossover points.

iGo insights – the smart tool

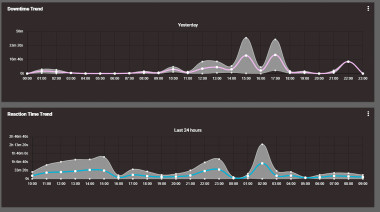

The AGVs are controlled and monitored by a transport and traffic control system. Transport orders are generated by the warehouse management system in the SAP host and transmitted to the control system. A huge quantity of valuable data is generated on this around the clock and is used to conduct a thorough analysis of the automatic warehouse and its processes from a top-level perspective in the Microsoft cloud server. With iGo insights, STILL offers an evaluation tool that filters all the available process information in the cloud and uses it to make connections and define specific recommendations. Warehouse Consultant Henrik Laursen says, “It’s with this that we can further optimise the availability and performance of our system.”

This smart tool uses the principle of machine learning to improve system performance. All data collected by the control system over a long period of time is uploaded to the cloud for evaluation. It can then be accessed online via the encrypted web portal at any time. So there is no need for any local infrastructure or hardware.

The AI-supported software recognises structures in this data flow, calculates probabilities and makes it possible to take proactive action, for example with scheduling servicing or repairs. The key figures relating to response times, traffic density, capacity utilisation and downtime are also used for monitoring purposes, and daily information on trends and anomalies is used to plan for the future. iGo insights is available on all web interfaces for desktops and mobile end devices. It also allows you to access multiple sites.

Smart service concept

iGo insights records all truck movements in heat maps in order to identify and optimise capacity bottlenecks. A playback function allows precise fault determination by looking back over truck and system behaviour. As Ole Lambrecht explains: “System errors can be resolved immediately via remote maintenance. If a fault occurs in an AGV, STILL Service responds within the hour. Fault codes are shown on the AGV display, read by the service team, and rectified immediately. This eliminates the need for a repair shop on site, thus further saving costs.”

Proximity warning system

The proximity warning system (ELOshield) comprises several components that communicate with one another via radio, together forming an all-in-one warning system. If a truck encounters a pedestrian, the stationary module detects its approach and emits a visual and acoustic signal. In the event of danger, the truck even slows down. Every forklift truck is automatically assigned a speed adjustment when entering and leaving the aisles. Aisles where manual order picking takes place are no-go zones for the AGVs. The stationary module offers greater protection for people and against collisions. It is also possible to set a speed limit for special areas. During manual order picking, AGVs in the aisle on the other side of this storage space are blocked from storing or retrieving a pallet. This prevents the danger of any accidents during picking.

Summary

Thanks to its scalability, the STILL iGo automatic warehouse in Tinglev responds very flexibly to turnover peaks. A satisfied Martin Jessen has the final word: “Our new warehouse has already risen to the challenge. While the warehouse was in operation, we could use the MX-X to manually set up the racks, one aisle at a time, for automatic operation. The initial analysis already showed a cost saving of around 20%.” The Tinglev warehouse is a true benchmark project as Danfoss is currently building a modern distribution centre in Rødekro using the same STILL technology. The centre is designed for automatic operation with 12 MX-X and 5 EXV trucks.