Electric Forklift Trucks RX 20 1.4 – 2.0 t

Our Powerhouse

- Load capacity 2000 kg

- Rated lift 7930 mm

- Speed 20 km/h

The STILL RX 20

Electrifying

For those who like to get things done.

You always want more? So do we. The STILL RX 20 delivers more in every capacity: more performance, more dynamism and more availability. The latest generation of STILL’s top-selling electric forklift truck is the best RX 20 that STILL ever developed.

In a warehouse, everything needs to be perfect. Therefore, the energetic RX 20 is not only powerful but also agile, getting you and your goods wherever you are going, fast. Plus, its excellent visibility and comfortable operator’s cabin allow you to work to the utmost level of precision. And all this with plenty of stamina, thanks to an unparalleled range of battery variants.

The RX 20 - ensures you get things done!

The "Simply Efficent" factors: Performance attributes as a measure of economic efficiency

Simply easy

Intuitive handling:

standard, easy-to-use operating concept across the whole RX product line

Efficiency-enhancing:

easy entry into a highly ergonomic driver’s cab

STILL Easy Control on-board computer:

all relevant information at a glance and performance functions just a click away

Ultra-fast:

easy-to-operate lateral battery change

Simply powerful

Intralogistics powerhouse:

highest handling performance of its class

Performance boost:

sprint mode for peak performance at the touch of a button

Optimum energy efficiency:

exceptionally long range with each battery charge

Intelligent support:

traction control and other assistance functions

Ready at all times:

optional STILL lithium-ion technology for maximum availability

Simply safe

Safe and precise handling:

high-precision hydraulics and agile driving dynamics

Safe entry:

large handle, anti-slip rubber mat and wide step

Optimal panoramic view:

slim mast and extra-large windows

Systematic safety:

optional pre-shift check on the display to help with the daily safety inspection

Safety for every application:

wide range of additional equipment options – from a direction indicator on the display to the Safety Light 4Plus safety lighting, as well Curve Speed Control for automatic speed reduction when cornering

Simply flexible

Customised control options:

multi-lever, mini-lever, Fingertip or Joystick 4Plus

Adjustable performance dynamics:

parameters such as driving and lifting speed can be adjusted to personal preferences at the touch of a button

Operating power tailored to your specifications:

wide variety of equipment options for every application

Flexible, decentralised charging:

Onboard Charger enables simple, fast and location-independent charging processes

Simply connected

Optimum networking:

optional interface for integration into fleet management software such as STILL neXXt fleet

Controlled use:

optional access control protects against incorrect operation

STILL Li-Ion Technology inside

The perfectly harmonised power system for reducing operating costs and increased truck availability.

More about STILL Li-Ion TechnologyIndependent forklift truck test F+H

„After the test drives we are impressed by the character of the RX 20. We haven‘t tested a truck that reacts faster to the driver‘s commands in this segment.“

„The new RX 20 can also convince us in terms of energy consumption. Even in the maximum setting, the test device is clearly below the average in this ranking.“

“...we achieve an arithmetical output of 430 pallets per eight hours. This means that the RX 20 surpasses the highest of us to date in of this forklift class.“

VerkehrsRundschau

"The STILL RX 20 is the best truck ever tested at the "Verkehrsrundschau."

Equipment options

Sharpening all senses: we can support you with our wide range of smart driver assistance systems and functions which will make your day-to-day work significantly easier. You will be able to drive in a safer, more comfortable, efficient and fatigue-free manner – in every driving situation.

Safety in the warehouse is increased thanks to an acoustic signal during reversing. Colleagues are therefore able to notice the forklift truck even if they have their back to it.

The broadband alarm is an audible alarm that emits a broadband signal tone. Over longer distances, the tone is drowned out by ambient noise. However, in the immediate environment the noise and thus the source of danger are very easy to locate. This increases awareness of the truck and prevents accidents.

Bracket systems protect drivers thanks to their stable structure and assembly within the truck contour. We also offer fitting and retrofitting for trucks with a rear windscreen. This does not restrict the freedom of movement or the all-round visibility of the driver, nor does it make getting on and off the truck more difficult. The manual system can be opened and closed by hand. The automatic system is coupled with the hand brake or accelerator pedal, and closes the bracket as soon as the truck begins to move.

The protective grille roof is available in a low or high version, according to the height of the passageways. It protects the driver from falling loads.

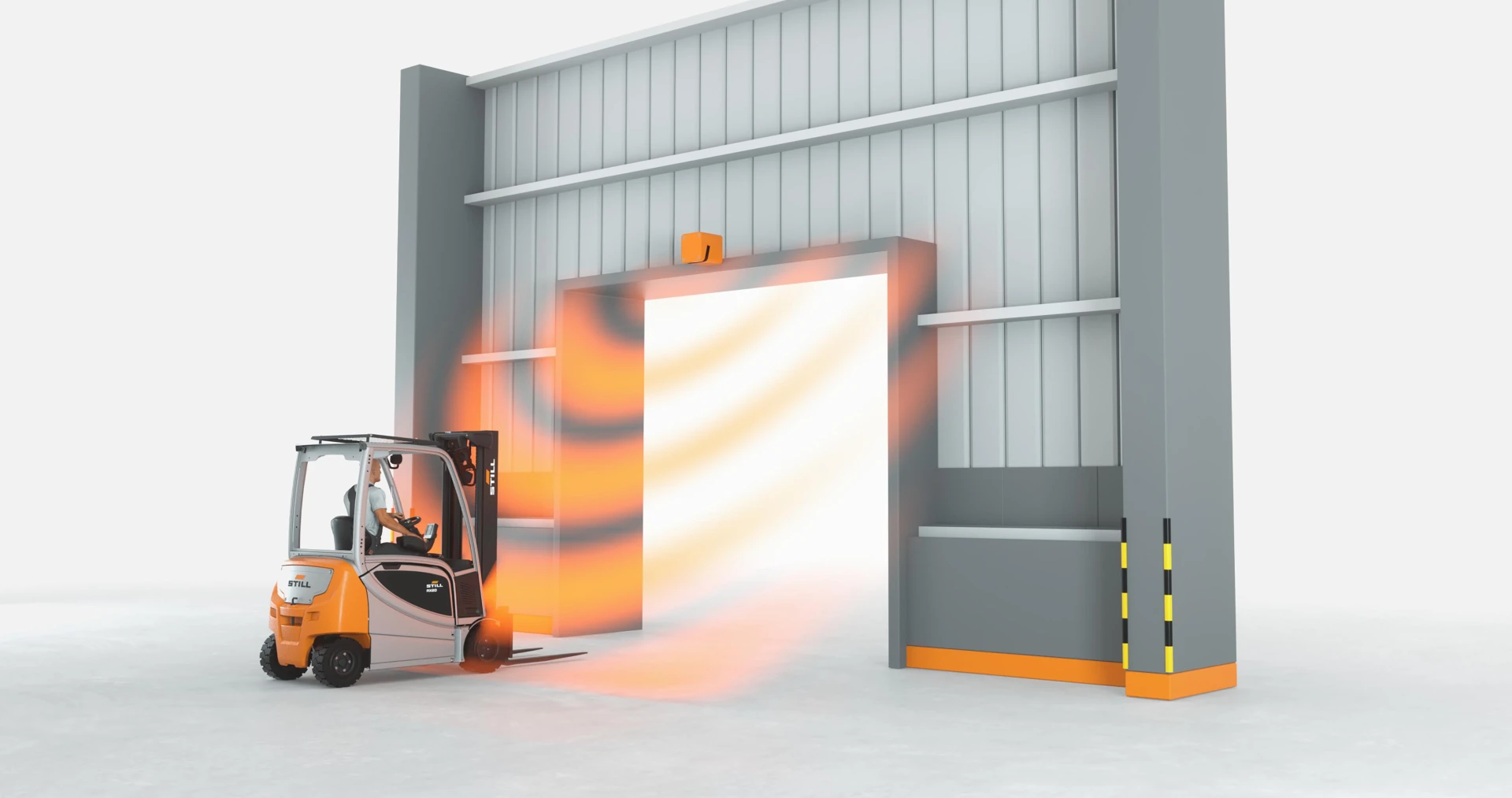

The wireless collision avoidance protects drivers, employees and trucks from dangerous situations, even without visibility. The system requires the truck to be pre-fitted with a set of antennae, a driver interface and a connection to the vehicle controller. It allows trucks, pedestrians and stationary wireless modules (e.g. on doors, entrances, hazard points) to communicate with each other. When trucks approach pedestrians, both parties receive an optical and acoustic warning (warning zone). In case of dangerous approaches (protection zone), they are alerted and interventions in the operation (braking) may be triggered. It therefore prevents ‘vehicle to pedestrian’ and ‘vehicle to vehicle’ collisions.

Keeping the goods in place: the load backrest stabilises the transported goods at the fork carriage back so that they can be securely transported from A to B.

Rear Area Monitoring with Intelligent Object Detection

The Reversing Assistant Plus is a camera-based assistance system designed for safe reversing. It displays the rear surroundings on the monitor and reliably detects people and objects.

- 3D camera with real-time display of the rear area

- Automatic distinction between people and objects

- Visual alerts and acoustic warnings in hazardous situations

- Context-based responses such as warning sounds or driving interventions

- Support for safe maneuvering in tight or unclear spaces

EasyBelt

Owing to the EasyBelt, the seat belt is already diagonally taut over the driver's seat. When stepping aboard, the driver only needs to climb into the pre-tensed belt. The quick and convenient handling of the EasyBelt makes buckling up a breeze.

Advantages to you:

- Cost-effective addition to the belt which ensures that the driver is able to properly secure their seat belt without effort

- Enables quick seat belt fastening and unfastening, thus having a positive effect on productivity

- High comfort level within the driver's work space due to the quick and easy handling of the seat belt – resulting in a high acceptance level from forklift truck drivers

- Easy to retrofit – EasyBelt can easily be retrofitted onto your fleet's counterbalanced forklift trucks

Sauermann restraint system

This system is available in different variants – mechanical or electric. A bracket system is installed on the side of the forklift truck which can be opened either manually or automatically. Each option ensures the highest level of operator protection and enables drivers to climb in and out of the forklift quickly and easily.

Safe reversing thanks to automatic warning

STILL Sentry protects people and objects behind the vehicle while reversing. The radar-based system reliably detects obstacles and warns the driver in time.

- Rear area monitoring via radar sensor

- Detection of objects and people within a customizable monitoring zone

- Acoustic warning signals and visual alerts in hazardous situations

- Increased safety when rear visibility is limited Ideal for operations involving frequent reversing or confined spaces

Buckled up? If not, the seat belt control ensures that the driving speed is automatically reduced. In cab trucks, the system only engages when the cab door is open.

If desired, you can limit the usage of your forklift truck to specific persons or groups of persons via access authorisation. Select whether the release of the truck should be carried out using a key switch or via a digicode system with ten configurable access codes (or PINs).

Learn more

Digicode systems (PIN) are an easy way to prevent unauthorised use of the truck. The truck can be started up quickly and easily, simply by entering the PIN code. This allows the user to limit access authorisation to specific individuals or groups. It is possible to configure up to ten PIN codes.

More informationOptimal visibility at all times: the optional panoramic overhead guard with armoured glass window provides improved visibility when storing and retrieving goods. It works entirely without the need for struts and of course meets all the safety standards of a standard overhead guard.

With Dynamic Load Control, you can ensure smooth, safe and efficient lifting operations by precisely detecting loads and lifting heights and automatically adjusting the hydraulics. Depending on the vehicle, different variants of the DLC are available to you. Increase productivity and safety - for fewer risks and optimum performance in daily use!

Learn more

Fulfills lifting height requirements at the push of a button:

Whether the racks are to be filled or emptied - you know the game: look closely, extend the mast, maintain concentrated eye contact, stop the mast, readjust if necessary. Several times. In every shift. On every day. Now imagine that you could leave your sense of proportion behind. Imagine you could just press a button and wait for the forks to float to exactly the right height and stop there automatically. Imagine: You can. With the STILL lift limiter, the forks automatically stop at up to three programmable intermediate lift heights. And to ensure that your profitability, but not your trucks, goes through the roof, the maximum lift height can also be permanently programmed.

Learn moreWith the help of the optional LED lift height sensor (standard on the FM-X), the lift height display ensures maximum precision from the very first millimetre. This means that operators always know the height of the fork tips and can navigate precisely to avoid touching the rack when picking up the pallet. The system works with a repeatability of less than +/- 5 mm and the lift height is permanently shown to the drivers on the display.

Learn moreThe ceiling sensor detects low ceiling heights and prompts the driver to reduce their speed in order to promote general work safety in the warehouse. It comprises an ultrasonic sensor on the roof of the truck, which detects ceilings up to a height of 20 m. Depending on the sensor signal, the maximum speed is controlled, whereby the standard speed is 6 km/h.

The right driving programme for all requirements: the operator can choose between three established and two freely configurable driving programmes in the three operating modes: Blue-Q, normal and sprint mode. The driving programmes can be chosen according to the situation in order to achieve the maximum performance or energy efficiency.

Intelligent autopilot: the forklift’s Blue-Q (blue button) efficiency mode is activated at the touch of a button. An intelligent optimisation characteristic in the drive saves energy precisely where it is not impacted by the work process.

Up to 10% savings in energy consumption depending on the use profile and forklift equipment.

And everything is on the right track:

Safe and undamaged vertical parking or storage of goods: This is exactly what you can do from now on at the push of a button with the mast vertical position assistance system. Once the system is activated, all you have to do is tilt the mast forwards. As soon as the mast is in the upright position, it stops automatically. This means that you always get the goods to the floor in one piece and store them on the shelves more quickly, easily and safely.

Learn more

Overload excluded:

If the forklift can still handle this load? A question that can quickly lead to injuries, vehicle or goods damage. Fortunately, there is overload detection. The system monitors the weight of the load and any attachments and always gives you a safe and clear answer. What's more, if the total weight exceeds the rated capacity or the set maximum load, the system actively intervenes and reduces the lifting speed. If the threshold value is exceeded by more than 10 percent, the lifting function is completely blocked. This means that the driver, vehicle and goods are always optimally protected.

Learn more

The driver can see the tilt angle of the mast on the display. They therefore always have the highest degree of control over the loaded goods. The function is a real help during storage and retrieval as well, as the operator is able to precisely check if the forks are holding the pallet correctly.

The wireless zone detection promotes general work safety thanks to automatic speed reduction in certain areas or by opening doors when a truck is approaching. It comprises a wireless system (incl. antennae set, driver interface and connection to the vehicle controller), which allows the truck, pedestrians and stationary wireless modules (on doors, entrances and hazard points) to communicate with each other.

Autostop before ground contact:

When forks hit the ground, it's not pleasant for the ears, the floor or the forklift. But on the other hand, would it not be very pleasant if this would not happen in the first place? That's exactly why we developed the electric fork wear protection for you. When the assistance system is activated, it ensures that the forks cannot touch the ground during lowering. Shortly before that, they stop automatically - exactly so that you can thread them perfectly into the pallet. Forks dragging on the ground due to accidental startup in the lowered state are also a thing of the past.

Learn moreQuiet lifting!

Strength lies in peace - this now also applies to your forklift trucks. Because the Silent Lift assistance system puts an end to noise during lifting and lowering operations. Smooth lift transitions, smooth storage and retrieval on the top shelf level, and an automatic stop of the forks before they hit the floor - all this promises you heavenly peace and quiet even when lifting and lowering the heaviest loads.

Learn more

The automatic parking brake is applied automatically or at the push of a button, and prevents the truck from rolling. The electrohydraulic spring-loaded brake locks whenever the truck stops.

Equipping forklift trucks with a fire extinguisher can help prevent the risk of fire. This should be clarified as part of the risk assessment. This enables fast and direct action in case of fire, thus preventing major damage.

Windows can be broken with the emergency hammer provided.

Better view of the load – more control at height

The fork tip camera system improves visibility of the load – especially at high lift heights. The camera is integrated directly into the fork tip and transmits the image to the driver’s monitor.

- Direct view of the load during loading and unloading

- Optimal control when working at great heights

- Reduced damage to goods and racking

- Camera safely integrated into the fork tip

- Real-time transmission to the in-cab display

Forks up, speed down:

More safety, less product breakage and ensuring proper vehicle use - these are the benefits offered by the Speed Reduction assistance system when the fork carriage is raised. As soon as the forks reach a height of 500 mm (or another defined threshold), the speed of the vehicle is automatically reduced. Even if a driver forgets that he should not drive with the load raised, the assistance system slows him down, guaranteeing safe handling of the load and vehicle.

Learn moreThe integrated horn is located on the handle to the rear of the overhead guard. The horn signal sounds at the push of a button. Thanks to this simple and ergonomic method of signalling, when reversing the driver can warn pedestrians in the area that the truck is approaching.

The panoramic mirror, which can be mounted on the left or right side of the truck, improves visibility and reduces the size of the blind spot by expanding the field of vision. Drivers are able to get a quick overview of what’s behind them, allowing them to work more safely.

More safety, more comfort: the optional positioning laser projects the fork height with a green laser line on the carrier, thus serving as a visual extension of the fork. This facilitates orientation when storing and retrieving goods, as well as increasing both the handling capacity and the degree of safety. The positioning laser can be easily switched on and off at the touch of a button and poses no threat to the naked eye.

The reversing light is a long, multi-coloured light on the back of the truck, which automatically emits a constant red light during forward travel and switches automatically to a flashing white light when the truck is in reverse.

The reversing light increases the visibility of the truck and thus reduces the risk of accidents as other traffic and pedestrians are able to easily identify the direction of travel.

The light, which is protected by a U-shaped frame, is anti-glare and can be attached to various points on the truck.

Safe operation at all times: the LED daytime driving light ensures that the forklift truck is always clearly visible even in darker areas. A daytime driving light is available for various trucks.

|

Model

|

Maximum capacity (kg)

|

Maximum lift height (mm)

|

Travel speed (km/h)

|

Battery voltage (V)

|

|---|---|---|---|---|

| RX 20-14C/Li-Ion | 1.400 | 7.870 | 20 | 48 |

| RX 20-16C/Li-Ion | 1.600 | 7.870 | 20 | 48 |

| RX 20-16/Li-Ion | 1.600 | 7.870 | 20 | 48 |

| RX 20-16L/Li-Ion | 1.600 | 7.870 | 20 | 48 |

| RX 20-18/Li-Ion | 1.800 | 7.720 | 20 | 48 |

| RX 20-18L/Li-Ion | 1.800 | 7.720 | 20 | 48 |

| RX 20-20L/Li-Ion | 2.000 | 7.930 | 20 | 48 |

| RX 20-16P/Li-Ion | 1.600 | 7.870 | 20 | 48 |

| RX 20-16PL/Li-Ion | 1.600 | 7.870 | 20 | 48 |

| RX 20-18P/Li-Ion | 1.800 | 7.720 | 20 | 48 |

| RX 20-18PL/Li-Ion | 1.800 | 7.720 | 20 | 48 |

| RX 20-20P/Li-Ion | 2.000 | 7.930 | 20 | 48 |

| RX 20-20PL/Li-Ion | 2.000 | 7.930 | 20 | 48 |

Downloads

The document provided for download is the updated version of the operating instructions for the standard truck. It does not include descriptions of customer options (Customer Option). For a concrete truck, please request the respective specific manual according to the serial number and the year of production from the STILL spare parts service.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday between 8 a.m. and 6 p.m

Use the contact form

Write to us – we will get back to you within 24 hours