Order Picker OPX-L 20

Thrillingly dynamic

- Shorter picking routes to pallets to enhance picking performance and ensure back-friendly picking thanks to the special vehicle design

- High driving dynamics in curves with an optimised centre of gravity

- Optional raisable driver's station for order picking in the first level

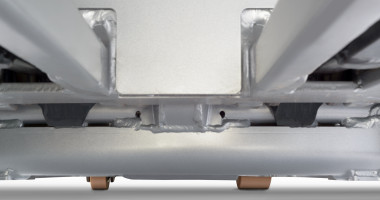

What do you do when the first pallet is fully loaded? With the OPX-L 20 you simply switch round to the second pallet on board and carry on picking, always on the shortest route to the next pallet. This is how it works: You load the picker with two empty pallets. One pallet is folded vertically upwards on the back of the fork and then the second is placed next to it. You can now start loading the horizontal pallet. After that work is done, the fully loaded pallet is simply lowered and the vehicle moved forward until the pallet reaches the fork tips.

The pallet on the back of the fork is now folded down onto the free part of the fork and work continues. Comfortable, back-friendly order picking of up to 2,000 kg at variable working heights of up to 891 mm. Thanks to the vehicle’s high driving stability, based on the low centre of gravity, the goods can be quickly brought to their destination even on curvy routes.

Simply easy

- High driving comfort due to height-adjustable, electric steering wheel with automatic neutral position

- Less need for training thanks to intuitive display and control unit

- Freedom of movement on the wide operator’s platform with optional extra narrow backrest

- Maximum energy savings with the ECO driving program

- iGo neo vehicles drive, steer, accelerate and brake independently and follow their operator at every turn

Simply safe

- Fatigue-free mounting and dismounting via the low vehicle entrance

- Excellent visibility thanks to LED daytime running light, Safety Light and Safety Light 4Plus

- Increased safety when cornering with Curve Speed Control and Dynamic Drive Control

- Less wear on the forks due to speed reduction with lowered forks

- iGo neo offers maximum safety for people in the warehouse environment thanks to a unique and multi-level safety concept

- Minimisation of impact damage even when the OPX iGo neo is driven manually

Simply connected

- Operator management, shock detection and access protection with FleetManager 4.x

- Early detection of a flat battery with the LED daytime running light Plus

- Integration into customer processes via automation interface and MMS preparation

- iGo neo: safe and reliable operator recognition thanks to the hybrid tracking system, even during Z-picking

Simply powerful

- High handling performance thanks to a load capacity of up to 2.000 kg

- Powerful, reliable and low-maintenance 3-kW three-phase AC traction motor

- Fast goods handling through powerful acceleration and a travel speed of up to 12 km/h

- iGo neo: up to 75 % less mounting and dismounting to relieve the operator; picking performance is significantly increased compared to conventional picking

Simply flexible

- High picking performance without mounting and dismounting thanks to pedestrian operation

- Fast order picking on the first level with fold-down step and raisable operator’s platform

- Prevention of back pain with optional air-cushioned driver’s stand and folding seat

- Flexible use of in-house batteries with the tray for batteries by other manufacturers

- OPX and OPX iGo neo as basic vehicles available in different variants according to the individual picking requirements

Equipment options

Sharpening all senses: we can support you with our wide range of smart driver assistance systems and functions which will make your day-to-day work significantly easier. You will be able to drive in a safer, more comfortable, efficient and fatigue-free manner – in every driving situation.

Keeping the goods in place: the load backrest stabilises the transported goods at the fork carriage back so that they can be securely transported from A to B.

Safety in every direction: an acoustic signal during reversing warns colleagues that a truck is approaching. They are therefore able to act promptly even if they have their back to the truck.

If desired, you can limit the usage of your forklift truck to specific persons or groups of persons via access authorisation. Select whether the release of the truck should be carried out using a key switch or via a digicode system with ten configurable access codes (or PINs).

Learn more

Digicode systems (PIN) are an easy way to prevent unauthorised use of the truck. The truck can be started up quickly and easily, simply by entering the PIN code. This allows the user to limit access authorisation to specific individuals or groups. It is possible to configure up to ten PIN codes.

More informationPerfectly suitable for vertical order picking at a height of up to 2.80 m. The platform can be lifted up to 1200 mm, whereby the storage area can be doubled with a second shelf level. Driving and steering is also possible with a lifted platform with STILL Easy Drive and STILL Easy Move for a high reloading performance.

Always in the right position: thanks to the height-adjustable backrest, the sitting position can be adjusted for the individual needs of the operator. This provides relief even during longer routes. There is also the option to couple the seat to the pneumatic suspension of the driver's cab as an option.

For occasional access:

the optional fold-out step is perfect for order picking at the first level with a reach height up to 2183 mm.

Saves space and quickly provides added comfort:

thanks to the ergonomic, height-adjustable, pneumatically cushioned folding seat, the operator can sit comfortably even on long routes.

Every step of the way: the optional pedestrian operation enables the operator to work highly efficiently as they no longer need to constantly climb in and out while transporting goods to various locations. The maximum speed during pedestrian operation is 4 km/h.

Floating instead of driving:

No matter how uneven the path: thanks to the perfectly pneumatically cushioned stand-on platform, human vibrations are reduced by up to 28%. The operator can therefore glide smoothly through the aisles – regardless of the condition of the floor.

Learn moreAutomatic speed adjustment for curves

The speed limiter controlled by steering angle reduces possible damage to goods by adapting to an appropriate cornering speed. This assistance function is available for various forklift trucks and warehouse technology devices, and regulates the driving speed automatically according to the steering angle. In other words, the driver doesn’t need to worry about speed when cornering. The truck automatically decelerates precisely as much as necessary for the operator to drive as safely but as quickly as possible.

Who can use which forklift truck for which area of application? How fast may a certain driver travel in the industrial truck?

The solution: our smart driver profiles in STILL Smart Portal. This web-based application allows the features of the truck to be adapted to the operator’s requirements, such as a reduction in travel, lifting or tilting speed or automatic activation of the lights.

The right driving programme for all requirements: the operator can choose between three established and two freely configurable driving programmes in the three operating modes: Blue-Q, normal and sprint mode. The driving programmes can be chosen according to the situation in order to achieve the maximum performance or energy efficiency.

Intelligent autopilot: the forklift’s Blue-Q (blue button) efficiency mode is activated at the touch of a button. An intelligent optimisation characteristic in the drive saves energy precisely where it is not impacted by the work process.

Up to 10% savings in energy consumption depending on the use profile and forklift equipment.

This feature prevents the pallet from lowering during travel. Faulty operation is thus prevented during travel and the goods are protected.

Safe operation at all times: the LED daytime driving light ensures that the forklift truck is always clearly visible even in darker areas. A daytime driving light is available for various trucks.

This involves slightly raising the fork end to secure the trolleys and thus the transport goods as well as possible during travel.

Downloads

The document provided for download is the updated version of the operating instructions for the standard truck. It does not include descriptions of customer options (Customer Option). For a concrete truck, please request the respective specific manual according to the serial number and the year of production from the STILL spare parts service.

|

Model

|

Maximum capacity (kg)

|

Maximum lift height (mm)

|

Travel speed (km/h)

|

Battery voltage (V)

|

|---|---|---|---|---|

| OPX-L 20 / Li-Ion | 2.000 | 800 | 12 | 24 |

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday between 8 a.m. and 6 p.m

Use the contact form

Write to us – we will get back to you within 24 hours