You can drive safely with us

Safety Assist

There are numerous causes for faulty processes – a lack of concentration, an incorrect assessment of situations, as well as environmental factors to which the driver is unable to react correctly or quickly enough. Our smart driver assistance systems not only continuously monitor the environment, thus providing guidance for the drivers, but can also actively intervene in certain events. They recognise potentially critical driving situations and are able to accelerate and decelerate independently. In addition to increased warehouse and operator safety, they also provide top performance with the highest level of energy efficiency thanks to the intelligent driving programmes.

Warning Zone Light/ Warning Zone Light Plus

Perfect addition to the STILL SafetyLight

The STILL warning zone light projects two strips of light to the left and right of the forklift truck. The optional illumination equipment serves as a visual warning for pedestrians and other drivers in the vicinity by projecting luminescent strips on the hall floor at the sides of the forklift truck.

The STILL Warning Zone Light Plus projects a semi-circle around the rear of the truck. This also increases awareness of the truck and marks a typical danger zone when approaching. This reduces the risk of pedestrian injury.

The STILL Warning Zone Light and the STILL Warning Zone Light Plus therefore perfectly complement the STILL Safety Light, which projects a blue cone of light in the front of the truck in the direction of driving.

STILL Easy Control

Safety first: digital guided Pre-Shift Check

With the Pre-Shift Check in the on-board computer STILL Easy Control STILL achieves a new level of safety for the driver and the truck: before the start of each shift, or at user-defined intervals, the driver must confirm the operational capability of the truck via the on-board computer before he can put the truck into operation with all its functions.

The customer is free to choose the criteria of the safety check. In addition to the standard query, several individual queries can be stored in the display of the on-board computer. And if an answer is negative? The customer has all options.

For example, he can define in the system that the performance of the vehicle is automatically limited if a query shows a negative test result.

For more security

- Pre-Shift Check

with STILL Easy Control on-board computer - Simple Pre-Shift Check

Confirmation by driver whether vehicle is ready for use - Advanced Pre-Shift Check

Customer-specific questions provide even more security - Vehicle restrictions

Limited performance adjustable in case of negative results - Truck ready for operation?

Are operating fluids (e.g. oil, water, fuel) visibly leaking?

Are the wheels damaged? Are they worn beyond permissible limits?

Is the capacity rating plate present, undamaged and legible?

Does the service brake work properly?

STILL SafetyLight 4plus

The visual warning system for fewer accidents

The blue warning light, STILL SafetyLight 4plus, significantly increases work safety in areas which are confusing or full of bends. The blue light spots are projected approx. 5 m in front of and behind the truck and warn people about the approaching truck to prevent impending collisions.

In areas with poor visibility or where there are a lot of turns, the STILL Safety Light and STILL Safety Light 4Plus provide a significant improvement in work safety. The blue light spots are projected approx. 5 m in front of and behind the truck and warn people about the approaching truck to prevent impending collisions.

How you benefit:

- Increase in the level of work safety for pedestrians and other parties involved in internal traffic thanks to fast responses even in areas with poor visibility.

- As the STILL Safety Light 4Plus also indicates the direction of the truck with its four light points, pedestrians are alerted to the truck even more quickly, giving them more time to react.

- Minimal impact on the truck operating time thanks to energy-efficient LED bulbs (5 W at 12 V)

- Maintenance-free operation and a long service life of 20,000 hours

- Minimal scattering and thus perfect visibility even on light-coloured floors.

STILL iGo pilot safety

Six in one sweep

Optimised braking paths: at the end of the aisle, the forklift truck decelerates gently in relation to the speed and lifting height, which increases handling capacity.

Automatic speed adjustment: in defined zones, speed adjustments can be set automatically based on the ground conditions.

Height limitation: The adjustable height limitation enables optimum use of the space below the roof for different hall heights.

Collision prevention: known obstacles can be defined. The driver does not need to memorise all particularities of the system and can concentrate on their work.

Aisle departure assistant: steering can be blocked for a defined stretch, e.g. when departing the aisle in order to prevent collisions.

Position selection: selection enables targeted movement into defined, often-used positions such as at transfer points.

Here you can find a full overview of all additional driver assistance systems and functions from STILL within the Safety Assist field.

Safety in the warehouse is increased thanks to an acoustic signal during reversing. Colleagues are therefore able to notice the forklift truck even if they have their back to it.

Who can use which forklift truck for which area of application? How fast may a certain driver travel in the industrial truck?

The solution: our smart driver profiles in STILL Smart Portal. This web-based application allows the features of the truck to be adapted to the operator’s requirements, such as a reduction in travel, lifting or tilting speed or automatic activation of the lights.

A flashing, warning or rotating light increases safety at the warehouse and makes other employees working in the warehouse aware of the forklift truck via a flashing yellow light signal. If preferred, this can be set to only light up when reversing. The use of this light increases safety particularly in areas where hearing protection is required to be worn. The rotating light is available in various designs and can be mounted on or behind the overhead guard.

To stop feet getting caught under tires – a rubber lip can be adhered to pedestrian vehicles for the protection of feet. An optional foot guard with a contact strip is available as a special feature which makes sure that the truck stops upon contact.

Safety in every direction: an acoustic signal during reversing warns colleagues that a truck is approaching. They are therefore able to act promptly even if they have their back to the truck.

Safe operation at all times: the LED daytime driving light ensures that the forklift truck is always clearly visible even in darker areas. A daytime driving light is available for various trucks.

Keeping the goods in place: the load backrest stabilises the transported goods at the fork carriage back so that they can be securely transported from A to B.

Buckled up? If not, the seat belt control ensures that the driving speed is automatically reduced. In cab trucks, the system only engages when the cab door is open.

If desired, you can limit the usage of your forklift truck to specific persons or groups of persons via access authorisation. Select whether the release of the truck should be carried out using a key switch or via a digicode system with ten configurable access codes (or PINs).

Leave nothing hanging on the balance: the system integrated in the FM-X reach truck virtually eliminates the risk of damaging goods when lifting pallets. The advantage of the shift and lowering lock is that pallets that have been lifted crookedly or diagonally lie on the wheel arms when they are lowered, and will therefore be tilted or pushed when pulling in the fork. The operator must always approve this for safety and is advised to check that the goods have been picked up correctly.

EasyBelt

Owing to the EasyBelt, the seat belt is already diagonally taut over the driver's seat. When stepping aboard, the driver only needs to climb into the pre-tensed belt. The quick and convenient handling of the EasyBelt makes buckling up a breeze.

Advantages to you:

- Cost-effective addition to the belt which ensures that the driver is able to properly secure their seat belt without effort

- Enables quick seat belt fastening and unfastening, thus having a positive effect on productivity

- High comfort level within the driver's work space due to the quick and easy handling of the seat belt – resulting in a high acceptance level from forklift truck drivers

- Easy to retrofit – EasyBelt can easily be retrofitted onto your fleet's counterbalanced forklift trucks

Sauermann restraint system

This system is available in different variants – mechanical or electric. A bracket system is installed on the side of the forklift truck which can be opened either manually or automatically. Each option ensures the highest level of operator protection and enables drivers to climb in and out of the forklift quickly and easily.

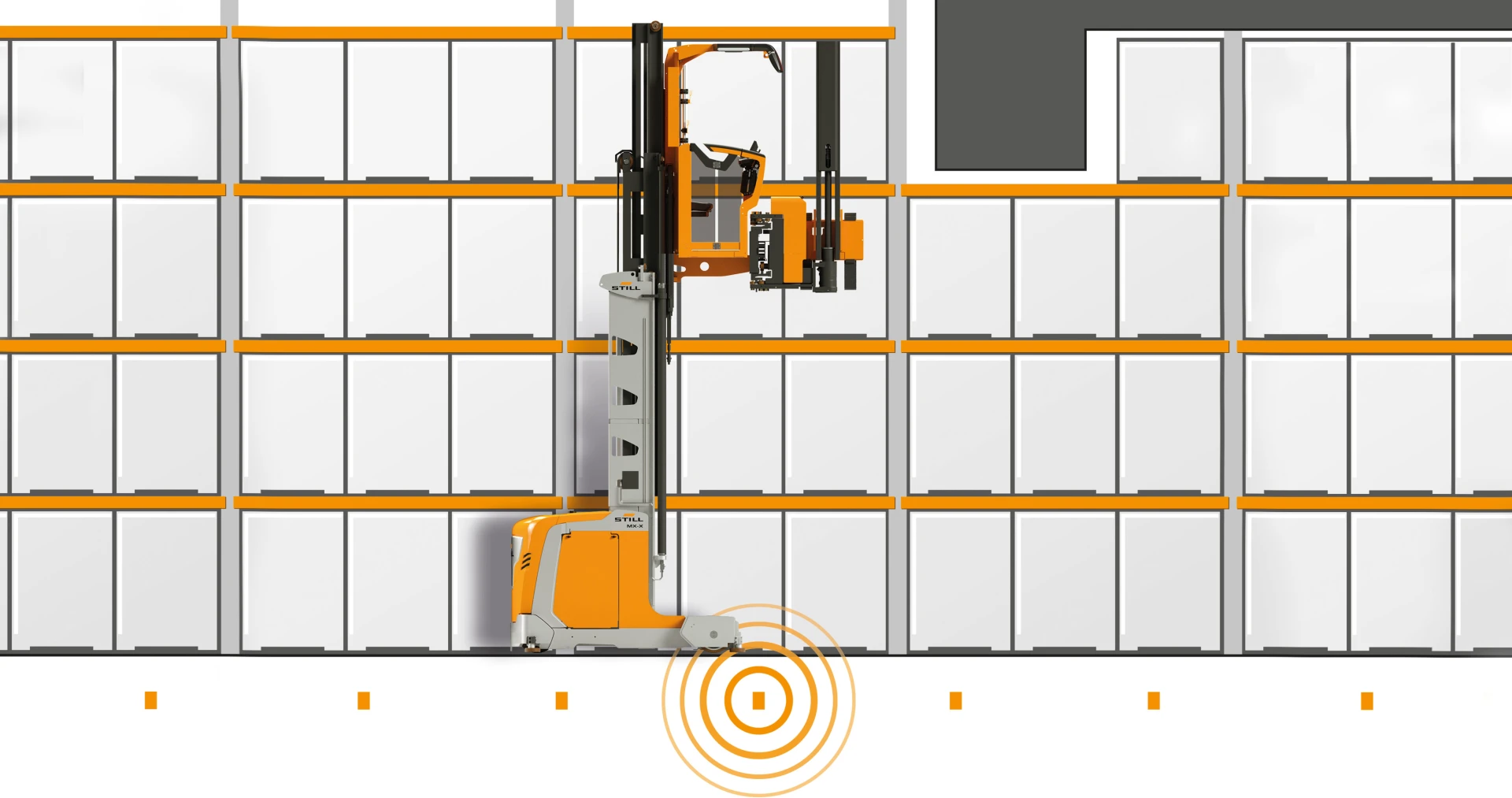

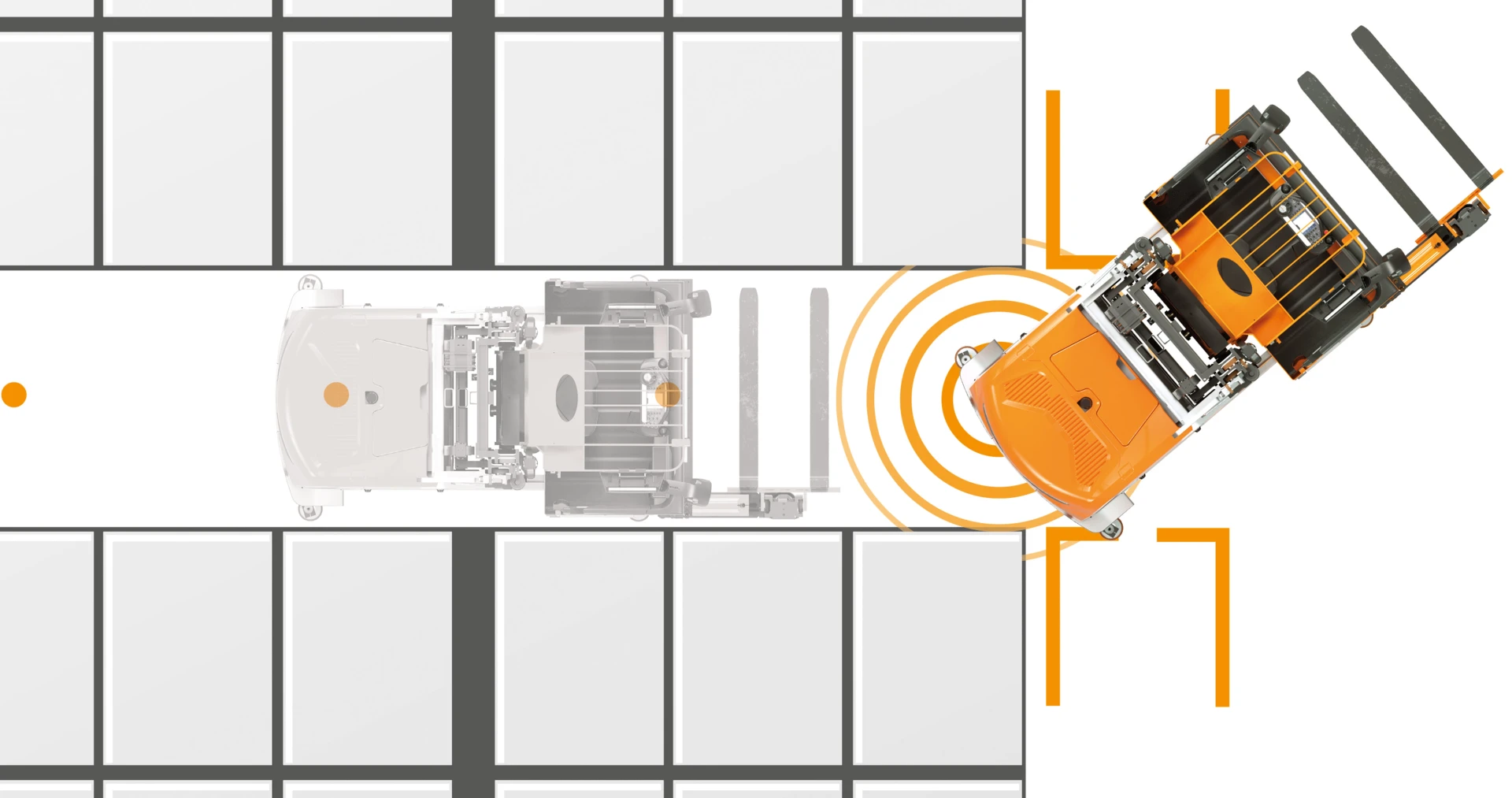

With the mobile personal protection system from STILL, you are on the safe side when it comes to protecting people in narrow aisles. Sensitive safety scanners on the drive and load sides of the VNA truck monitor the route and reliably detect people in the aisle. Thanks to the latest scanner technology, the STILL PPS meets all legal requirements for occupational health and safety and workplace regulations - in a lean and efficient way.

Early braking in narrow aisle operation

The Predictive Braking System detects obstacles in narrow aisles at an early stage and initiates automatic responses depending on the situation – for greater safety in tight spaces.

- Detection of static obstacles up to 8 meters away

- Definition of warning and protection zones with individual configuration

- Automatic responses: warning signal, speed reduction, or vehicle stop

- Easy integration into new or existing vehicles

- Ideal for narrow aisle warehouses with high traffic density and limited visibility

The unit decelerates automatically during the trip if it is approaching the end of the aisle. There are five different options for this:

- With speed reduction at both open aisle ends It is always possible to drive toward the middle of the aisle at maximum speed. From the beginning of the aisle end zone, the speed is reduced to 2.5 km/h.

- With absolute stop: Speed reduction at the open aisle end as well as speed reduction and absolute stop at the closed aisle end. It is always possible to drive toward the middle of the aisle at maximum speed. From the beginning of the aisle end zone, speed is reduced to 2.5 km/h. At the closed aisle end, the unit is decelerated to a halt with the absolute stop. A positioning movement toward the end of the aisle is possible with the acknowledgement button.

- With stop at both open aisle ends. It is always possible to drive toward the middle of the aisle at maximum speed. The unit is decelerated to a halt from the beginning of the aisle end zones. Our technicians can set the parameters for clearance to continue driving at a reduced speed of 2.5 km/h toward the aisle end.

- With stop and absolute stop: Stop at the open aisle end as well as stop and absolute stop at the closed aisle end. It is always possible to drive toward the middle of the aisle at maximum speed. The unit is decelerated to a halt from the beginning of the aisle end zones. Our technicians can set the parameters for clearance to continue driving at a reduced speed of 2.5 km/h toward the aisle end. The unit is decelerated to a halt at the closed aisle end, and a positioning movement toward the end of the aisle is then possible with the acknowledgement button.

- With absolute stop at the closed aisle ends and speed reduction at the open aisle ends. It is always possible to drive toward the middle of the aisle at maximum speed. From the beginning of the aisle end zones, the unit is decelerated at the open aisle end to 2.5 km/h, and brought to a halt at the closed aisle end. The unit is cleared for continued driving using the acknowledgement button to depart the aisle at a maximum speed of 2.5 km/h.

The smart rescuer in an emergency: if the operator performs an atypical action which suggests a medical emergency, an acoustic and optical emergency signal will sound to alert colleagues to the situation.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday between 8 a.m. and 6 p.m

Use the contact form

Write to us – we will get back to you within 24 hours