Safely on track

Drive Assist

Our smart driver assistance systems detect potentially critical driving situations and are able to brake automatically. In addition to increased warehouse and operator safety, they also provide top performance with the highest level of energy efficiency thanks to the intelligent driving programmes.

Active Floor Compensation (AFC)

So that everything runs smoothly – even if the floor doesn't

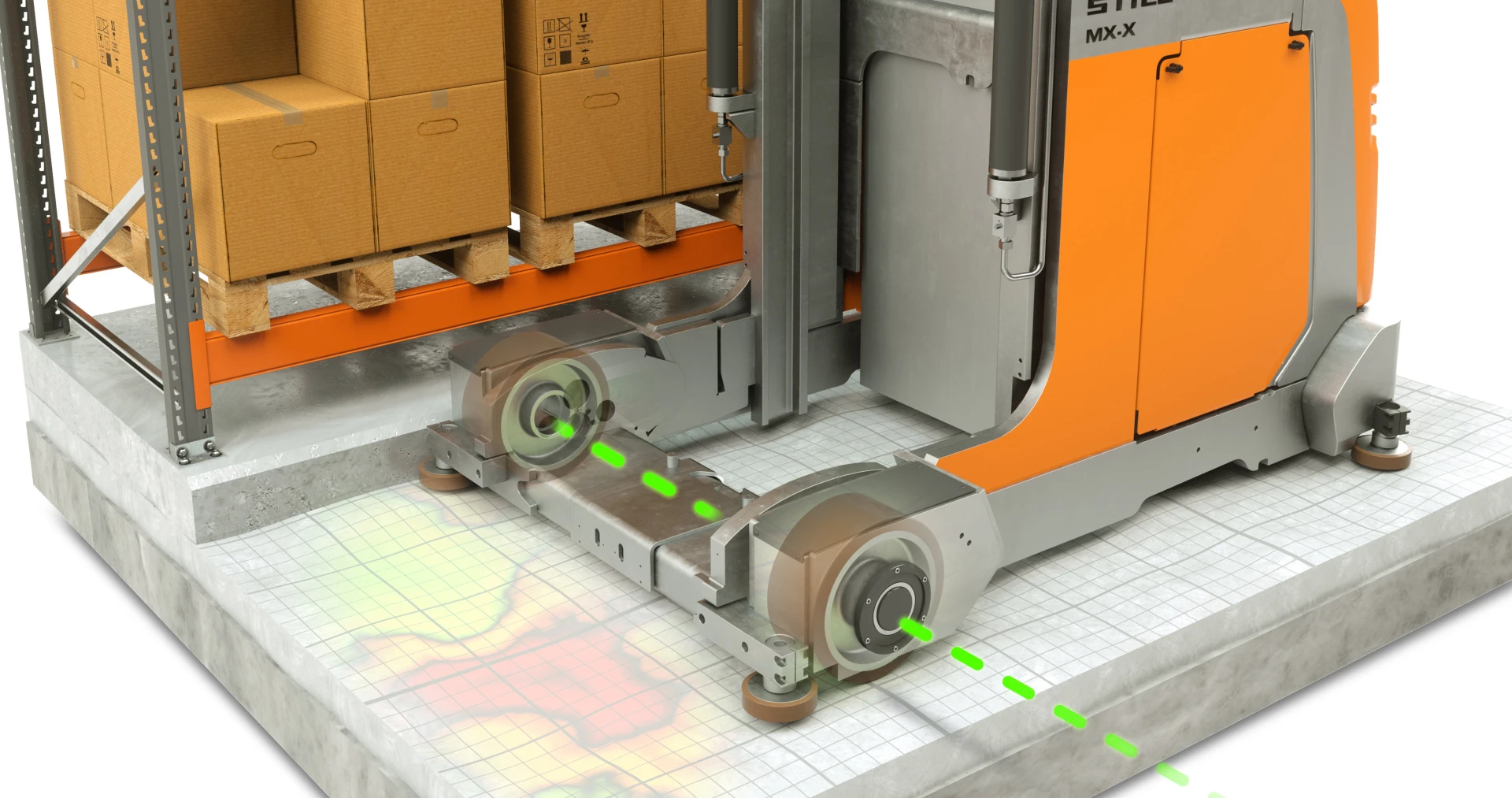

Active Floor Compensation (AFC) for STILL VNA trucks MX-X l – maximum performance even on uneven floors.

With the assistance system for the MX-X Very Narrow Aisle Truck, we offer a genuine alternative to reconditioning the warehouse floor. The system identifies any uneven surfaces in the load wheels’ path and compensates for them in real time. This ensures that the truck frame always remains horizontal and the mast vertical. The AFC system – the only one of its kind on the market – has ultra-fast processors which allow it to react instantaneously, even when travelling at top speeds. In contrast to passive systems that only have a dampening effect, this system actively prevents vibrations before they occur.

So that everything runs smoothly – even if the floor doesn't

Active Floor Compensation (AFC) for STILL VNA trucks MX-X l – maximum performance even on uneven floors.

With the assistance system for the MX-X Very Narrow Aisle Truck, we offer a genuine alternative to reconditioning the warehouse floor. The system identifies any uneven surfaces in the load wheels’ path and compensates for them in real time. This ensures that the truck frame always remains horizontal and the mast vertical. The AFC system – the only one of its kind on the market – has ultra-fast processors which allow it to react instantaneously, even when travelling at top speeds. In contrast to passive systems that only have a dampening effect, this system actively prevents vibrations before they occur.

Curve Speed Control

Automatic speed adjustment for curves

The speed limiter controlled by steering angle reduces possible damage to goods by adapting to an appropriate cornering speed. This assistance function is available for various forklift trucks and warehouse technology devices, and regulates the driving speed automatically according to the steering angle. In other words, the driver doesn’t need to worry about speed when cornering. The truck automatically decelerates precisely as much as necessary for the operator to drive as safely but as quickly as possible.

STILL tiller with Optispeed function

Works at any angle

Depending on the tiller angle, the OptiSpeed tiller steering automatically ensures that the maximum driving speed is adapted to the angle. If the angle becomes sharper, the truck decelerates automatically. The tiller steering helps to ensure safe movement even in tight spaces.

The operator is thus able to steer easily and work ergonomically.

The OptiSpeed combi tiller is available as an option for all conventional STILL pallet trucks.

Fork wear protection (Silent Mast)

Autostop before ground contact:

When forks hit the ground, it's not pleasant for the ears, the floor or the forklift. But on the other hand, would it not be very pleasant if this would not happen in the first place? That's exactly why we developed the electric fork wear protection for you. When the assistance system is activated, it ensures that the forks cannot touch the ground during lowering. Shortly before that, they stop automatically - exactly so that you can thread them perfectly into the pallet. Forks dragging on the ground due to accidental startup in the lowered state are also a thing of the past.

Here you can find a full overview of all additional driver assistance systems and functions from STILL within the Drive Assist field.

The forklift truck travels at creep speed (5 km/h) with a defined lift height. This significantly reduces the risk of an accident as the driver has sufficient time to react promptly in the event of a hazardous situation.

Forks up, speed down:

More safety, less product breakage and ensuring proper vehicle use - these are the benefits offered by the Speed Reduction assistance system when the fork carriage is raised. As soon as the forks reach a height of 500 mm (or another defined threshold), the speed of the vehicle is automatically reduced. Even if a driver forgets that he should not drive with the load raised, the assistance system slows him down, guaranteeing safe handling of the load and vehicle.

Every step of the way: the optional pedestrian operation enables the operator to work highly efficiently as they no longer need to constantly climb in and out while transporting goods to various locations. The maximum speed during pedestrian operation is 4 km/h.

The right driving programme for all requirements: the operator can choose between three established and two freely configurable driving programmes in the three operating modes: Blue-Q, normal and sprint mode. The driving programmes can be chosen according to the situation in order to achieve the maximum performance or energy efficiency.

Intelligent autopilot: the forklift’s Blue-Q (blue button) efficiency mode is activated at the touch of a button. An intelligent optimisation characteristic in the drive saves energy precisely where it is not impacted by the work process.

Up to 10% savings in energy consumption depending on the use profile and forklift equipment.

To increase safety during storage and picking operations, the driving speed reduces automatically from a lifting height of 300 mm. If the forks are raised above the "desired value of up to 500 mm" during the drive, the speed of the forklift truck is also reduced automatically.

Fatigue-free operation thanks to the electrical steering unit: you can easily adjust the tiller length for adequate distance between the operator and truck. For the driver, this means a significant increase in safety as well as a more efficient work flow. The maximum driving speed is increased to 6 km/h when the combi-tiller is extended.

The compactly bundled basic safety package: the intelligent Assistant Truck Control driver assistance system features several functions which detect potentially critical driving situations and indicate these to the operator, or even act independently.

The following features are included in this driver assistance system:

- Safe exit/parking: a warning tone is sounded if the seat is vacated but the parking brake is not applied. This prevents unsecured truck from being parked.

- Seat belt controls: the driving speed is automatically reduced if the seat belt is not worn. In cab trucks, the system only engages when the cab door is open. The operator also receives a reminder to wear the seat belt.

- Speed limiter controlled by steering angle (Curve Speed Control): the driving speed is automatically adapted when taking curves. Through the speed limiter controlled by steering angle, possible damage to goods is reduced owing to the appropriate cornering speed.

- Speed limiter with raised forks: if the forks are raised above the "desired value of up to 500 mm" during the drive, the speed of the forklift truck is reduced automatically. The advantage of this is that you can drive safely even when the forks are raised.

Smart orientation: forklift trucks which move via inductive forced steering or mechanical forced operation are able to detect if they are in the correct warehouse aisle thanks to the contact-free aisle detection.

Maximum handling capacity: STILL OptiSpeed

The package comprises comprehensive hardware and software assistance systems which optimise the movements of the truck regardless of the load. This significantly increases handling capacity. OptiSpeed uses software to determine optimum fork and travel movements depending on the lifting height. The system offers continuous adjustment of the driving speed in the aisle, independent of the lifting height. This ensures added volume capacity, comfort and safety.

The OptiSpeed 3.3 variant combines the advantages of previous variants with a weight sensor: in addition to the visual and acoustic signals when specific limit values are reached, a travel and lift stop is triggered when the permissible load weight is exceeded. The system calculates ideal transport movements and optimises them based on the lifting height and load. That enables higher speeds on empty runs or when loading and picking.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday between 8 a.m. and 6 p.m

Use the contact form

Write to us – we will get back to you within 24 hours