High lift pallet truck EXV 14-20

Power meets innovation

- Load capacity 2000 kg

- Rated lift 6066 mm

- Speed 6 km/h

Stronger and more intelligent than the rest – that’s the STILL EXV 14-20 high lift pallet truck. Two of its outstanding features are its huge residual load capacity and its smart colour display. The latter provides the operator with basic information, the truck status or the battery charge status at a glance, and different language-independent symbols provide optimum support in operation. The smart and extremely mobile warehouse organiser moves pallets weighing up to 2,000 kg quickly, safely and reliably. Its powerful, low- maintenance motor and precise controls, suitable for both left- and right-handed operators, enable it to achieve unprecedented pallet turnover rates.

The letters EXV are not, however, just synonymous with quick goods handling, but with safe goods handling as well. The optional load capacity diagram and Dynamic Load Control shows what is possible. The curved tiller shape and the sensitive impact plate protect the driver, and the EXV stops automatically when the tiller is released – even on ramps. The OptiSpeed tiller also adjusts the speed of the EXV to the distance from the operator, while the Curve Speed Control system regulates the speed around bends. This high lift pallet truck, which is as strong as it is smart, allows you to always keep your flow of goods safely under control; from transporting loads within the pre-storage area to operating the shelving system.

Optimum utilisation of storage area:

high storage compaction due to very high residual load capacity

Everything in view, all the time:

colour display with a range of language-independent symbols shows you all of the important functions at a glance

Always available:

battery capacities of up to 375 Ah and Li-Ion enable long periods of operation

The "Simply Efficent" factors: Performance attributes as a measure of economic efficiency

Simply easy

Flexible, intuitive operation of all control elements on the tiller head

with one hand, without the need to change grip, naturally for both left- and right-handed operators

Reliable availability

thanks to large colour display with battery status display

Optimal ergonomics and reduced physical strain for the operator

thanks to electric driving, lifting and lowering functions

Clear view through the mast to the fork tips

facilitates hassle-free pallet handling

Unbeatable handling performance:

powerful motor, high residual load capacity and responsive control elements

With iGo vehicles,

additional vehicles can be added at any time so as to expand transportation capacity

Simply powerful

Power meets safety:

the four-wheel chassis ensures outstanding stability and effective performance

Reliable excellent performance

thanks to the powerful yet low- maintenance AC motor

New level of precision and safety for user and load

thanks to the responsive proportional valve control

Optimal availability, low-maintenance and high performance

thanks to the optional lithium-ion technology

Smooth and precise electrical steering

Software‑based transport controls for the EXV iGo

enable optimal fleet utilisation, whilst guaranteeing a high level of process reliability, traffic management, visualisation of truck movements, battery charge status monitoring and reduced error rates – the flow of materials and information is always reliable and mapped comprehensively and transparently

Simply safe

Maximum driver safety

thanks to the low-entry truck frame and load backrests

Initial lift ensures stable and low-vibration driving performance,

even if there are slight gradients or unevenness in the floor

Safety for man and machine:

OptiSpeed tiller and automatic stop mechanism when the tiller is released

Safe manoeuvring even in restricted space

thanks to creep speed mode

Information on the lift height at a glance

– on the coloured load capacity display

Estimate the load correctly:

Dynamic Load Control can be used to estimate the load and the corresponding maximum lift height

EXV iGo

improves transport quality and eliminates the risk of injury and damage to people, trucks, warehouse equipment and goods thanks to smart safety functions

Simply flexible

Precision even in confined spaces

thanks to compact dimensions

Well-equipped for a wide range of applications

with different driving programmes

Ready for use at all times:

the battery can be charged and interim charged flexibly from any location without the need for a fixed charging station

iGo trucks can also be operated manually if required:

this increases flexibility, safeguards process and material flow and enables easy access to goods

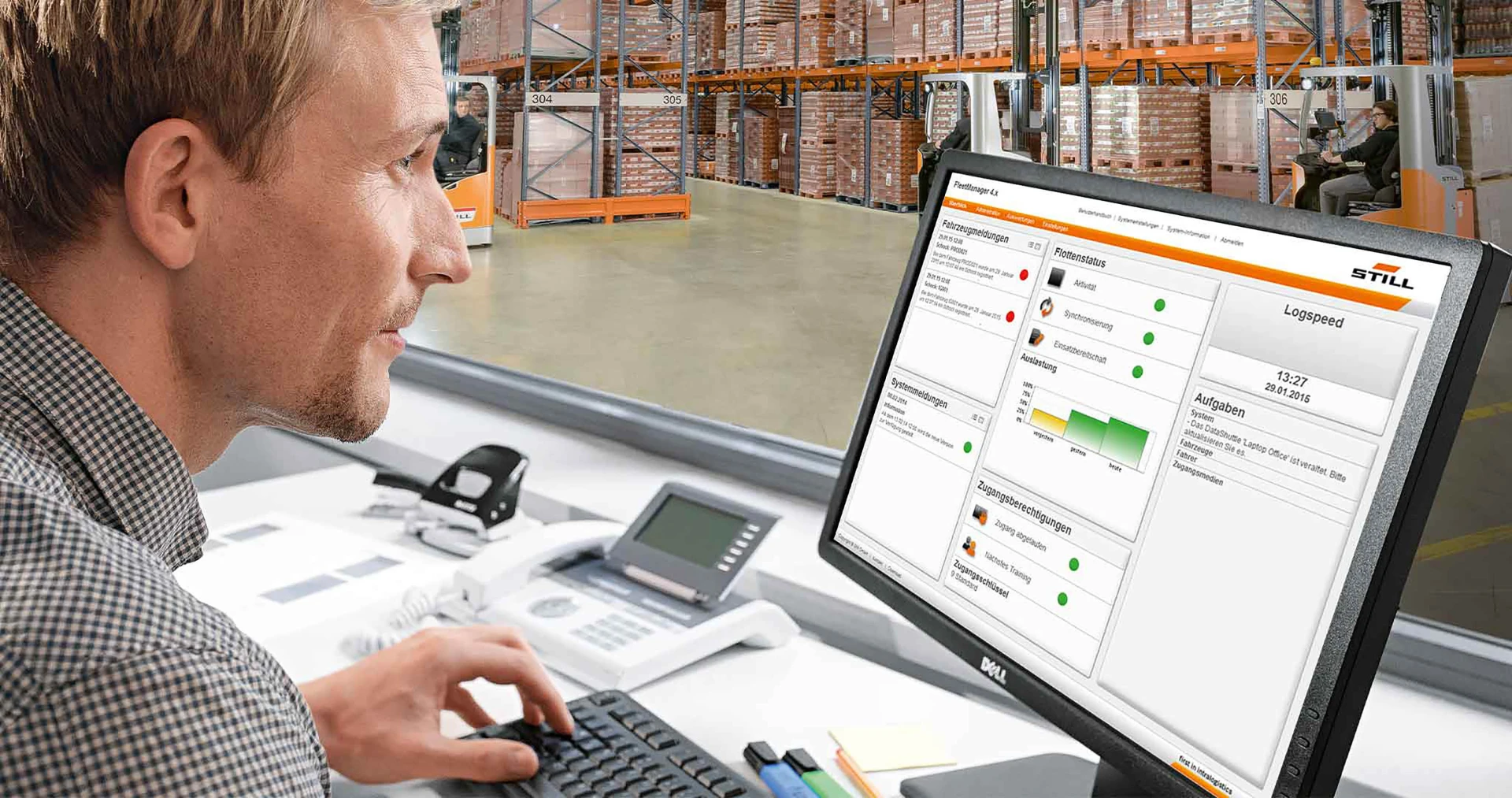

Simply connected

Compact information:

all relevant truck information is available at a glance in the STILL neXXt fleet web application.

Innovative STILL FleetManager keeps driver and truck safe:

operator management and shock detection as well as damage and cost minimisation thanks to access protection

Optimisation of the goods flow

thanks to straightforward connection to existing material flow management systems via MMS provision

Different iGo trucks can be combined

with one another, and with manual transport systems and stationary automation systems

STILL Li-Ion Technology inside

The perfectly harmonised power system for reducing operating costs and increased truck availability.

More about STILL Li-Ion TechnologyEquipment options

Sharpening all senses: we can support you with our wide range of smart driver assistance systems and functions which will make your day-to-day work significantly easier. You will be able to drive in a safer, more comfortable, efficient and fatigue-free manner – in every driving situation.

Keeping the goods in place: the load backrest stabilises the transported goods at the fork carriage back so that they can be securely transported from A to B.

The ‘shock detection’ function helps to reduce unusual impact and to minimise the costs incurred as a result of impact damage. It consists of a sensor that measures vibrations in the truck. Should the vibrations exceed a certain level, the impact will be registered as unusual and the fleet manager is informed, who can then train the driver to handle the truck correctly.

More informationIf desired, you can limit the usage of your forklift truck to specific persons or groups of persons via access authorisation. Select whether the release of the truck should be carried out using a key switch or via a digicode system with ten configurable access codes (or PINs).

Learn more

Digicode systems (PIN) are an easy way to prevent unauthorised use of the truck. The truck can be started up quickly and easily, simply by entering the PIN code. This allows the user to limit access authorisation to specific individuals or groups. It is possible to configure up to ten PIN codes.

More information

Works at any angle

Depending on the tiller angle, the OptiSpeed tiller steering automatically ensures that the maximum driving speed is adapted to the angle. If the angle becomes sharper, the truck decelerates automatically. The tiller steering helps to ensure safe movement even in tight spaces.

The operator is thus able to steer easily and work ergonomically.

Automatic speed adjustment for curves

The speed limiter controlled by steering angle reduces possible damage to goods by adapting to an appropriate cornering speed. This assistance function is available for various forklift trucks and warehouse technology devices, and regulates the driving speed automatically according to the steering angle. In other words, the driver doesn’t need to worry about speed when cornering. The truck automatically decelerates precisely as much as necessary for the operator to drive as safely but as quickly as possible.

With Dynamic Load Control, you can ensure smooth, safe and efficient lifting operations by precisely detecting loads and lifting heights and automatically adjusting the hydraulics. Depending on the vehicle, different variants of the DLC are available to you. Increase productivity and safety - for fewer risks and optimum performance in daily use!

Learn moreThe right driving programme for all requirements: the operator can choose between three established and two freely configurable driving programmes in the three operating modes: Blue-Q, normal and sprint mode. The driving programmes can be chosen according to the situation in order to achieve the maximum performance or energy efficiency.

Intelligent autopilot: the forklift’s Blue-Q (blue button) efficiency mode is activated at the touch of a button. An intelligent optimisation characteristic in the drive saves energy precisely where it is not impacted by the work process.

Up to 10% savings in energy consumption depending on the use profile and forklift equipment.

To stop feet getting caught under tires – a rubber lip can be adhered to pedestrian vehicles for the protection of feet. An optional foot guard with a contact strip is available as a special feature which makes sure that the truck stops upon contact.

Stability at all times: the optional load capacity display shows the user the current lift height and the associated residual load capacity at all times. The load capacities and lift heights are displayed on the coloured signs attached directly to the mast.

|

Model

|

Maximum capacity (kg)

|

Maximum lift height (mm)

|

Travel speed (km/h)

|

Battery voltage (V)

|

|---|---|---|---|---|

| EXV 14 (i) / Li-Ion | 1.400 | 6.066 | 6.0 | 24 |

| EXV 14 D / Li-Ion | 1.400 | 6.066 | 6.0 | 24 |

| EXV 16 (i) / Li-Ion | 1.600 | 6.066 | 6.0 | 24 |

| EXV 16 D / Li-Ion | 1.600 | 6.066 | 6.0 | 24 |

| EXV 20 (i) / Li-Ion | 2.000 | 4.476 | 6.0 | 24 |

| EXV 20 D / Li-Ion | 2.000 | 4.476 | 6.0 | 24 |

| EXV iGo /Li-Ion | 2.000 | 3.000 | 6.0 | 24 |

Downloads

The document provided for download is the updated version of the operating instructions for the standard truck. It does not include descriptions of customer options (Customer Option). For a concrete truck, please request the respective specific manual according to the serial number and the year of production from the STILL spare parts service.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday between 8 a.m. and 6 p.m

Use the contact form

Write to us – we will get back to you within 24 hours