Material flow management

Software modules for intralogistics

- Optimal mapping and efficient control of material flow

- Optimal utilisation of transport resources

- Extensive analysis options

- Integrated system with hardware and software

- Simple communication of system components

- High flexibility thanks to modular design

- Fast implementation thanks to simple connection

- Future-proof thanks to scalability

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday between 8 a.m. and 6 p.m

Use the contact form

Write to us – we will get back to you within 24 hours

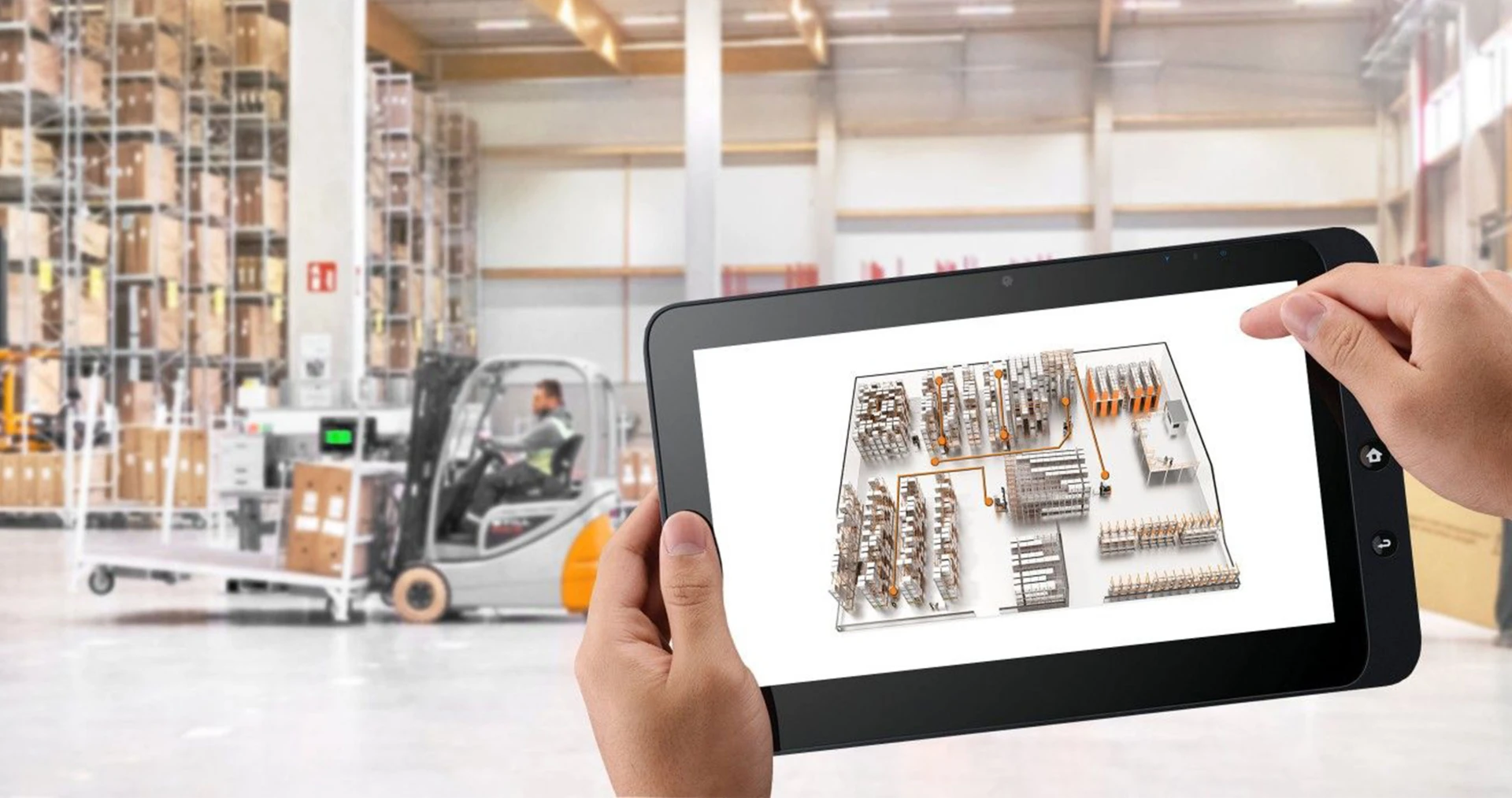

The modules of the STILL Material Flow Management System form a complete warehouse management system (WMS) that can be used to control, map and analyse all flows of goods and information along the entire intralogistics chain. The system can be used for several locations and a wide range of industries from production, trade and services. In the STILL system solution, all hardware and software components, from the STILL terminal to warehouse management and the order-picking system, are modular and coordinated with each other.

- Optimal mapping and efficient control of material flow

- Optimal utilisation of transport resources

- Extensive analysis options

- Integrated system with hardware and software

- Simple communication of system components

- High flexibility thanks to modular design

- Fast implementation thanks to simple connection

- Future-proof thanks to scalability

- Modern, update/release-capable system architecture for hardware, software and integration into existing customer systems

- Flexible use of the warehouse management, transport and/or order picking system as a stand-alone solution or modules of the STILL MMS

- Connection of STILL driver assistance systems and STILL automation solutions for optimum truck utilisation in the warehouse

- Hardware tailored to the application and vehicle (e.g. electrical and mechanical preparation for STILL terminals as well as printers and scanners)

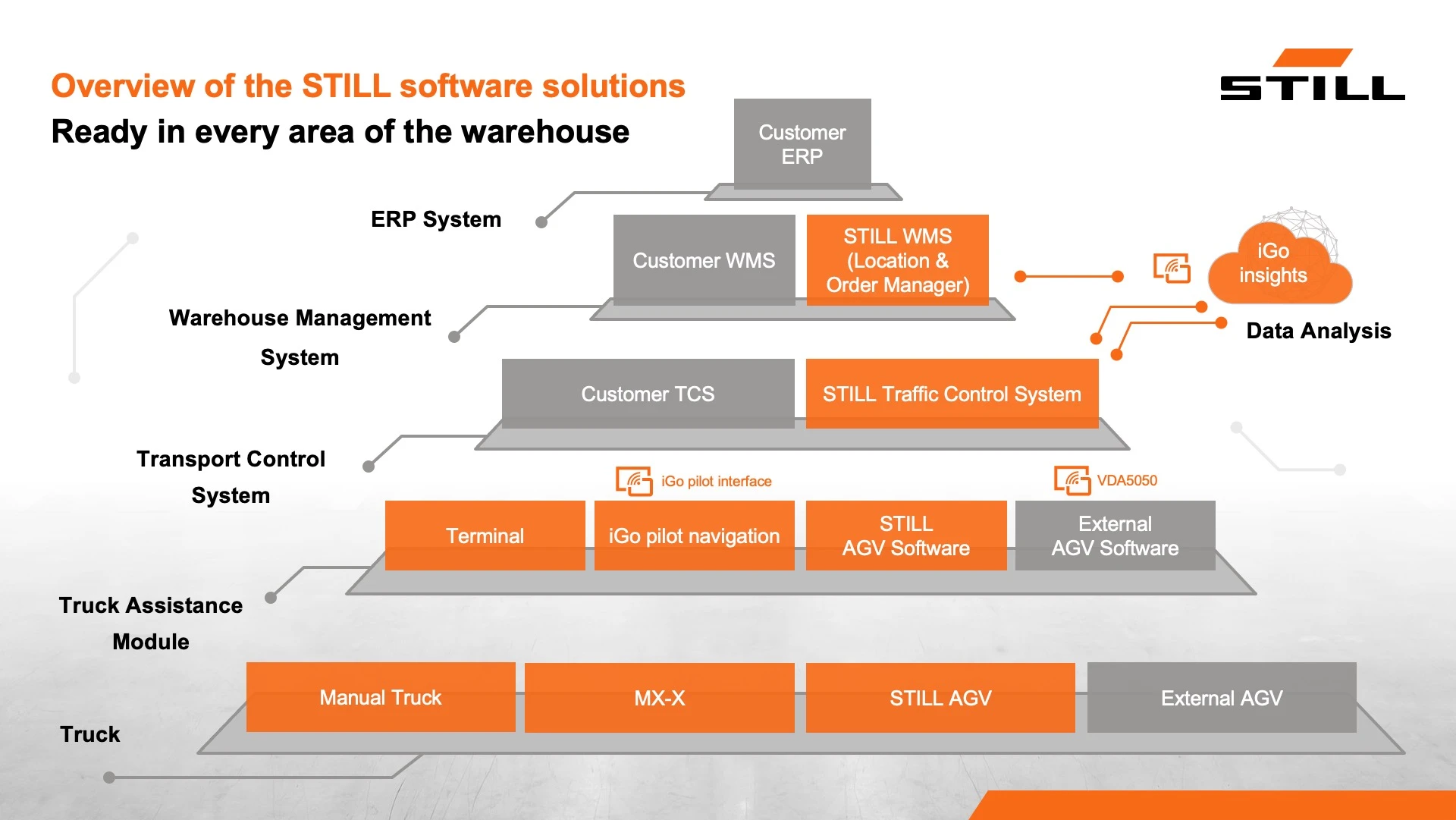

STILL's software solutions aim to ensure efficient interaction at all levels of warehouse logistics, from the operational truck level to transport and inventory management.

- Level: ERP merchandise management system (e.g. SAP)

- Level: Warehouse Management System - Solution "STILL Warehouse management system" (docked iGo insights)

- Level: Transport control system - solution "STILL Vehicle guidance system" (docked iGo insights)

- Level: Vehicle Assistance Modules - Solutions Terminal, iGo pilot navigation, AGV Software

- Level: Vehicle - Solution "Manual vehicles, semi-automated vehicles, automated guided vehicles (AGVs)

Warehouse management system

The warehouse management system organises stock and location management. The question "where are how many articles?" is answered here and transferred to the enterprise resource planning system (ERP). With the warehouse management system, all goods movements can be individually controlled: from goods receipt to warehouse control and order picking to tour provision and loading in goods issue. There are different system solutions for warehouse management systems. Of course, existing, proprietary solutions can also be used. Data communication takes place via terminals, standardised interfaces or corresponding middleware.

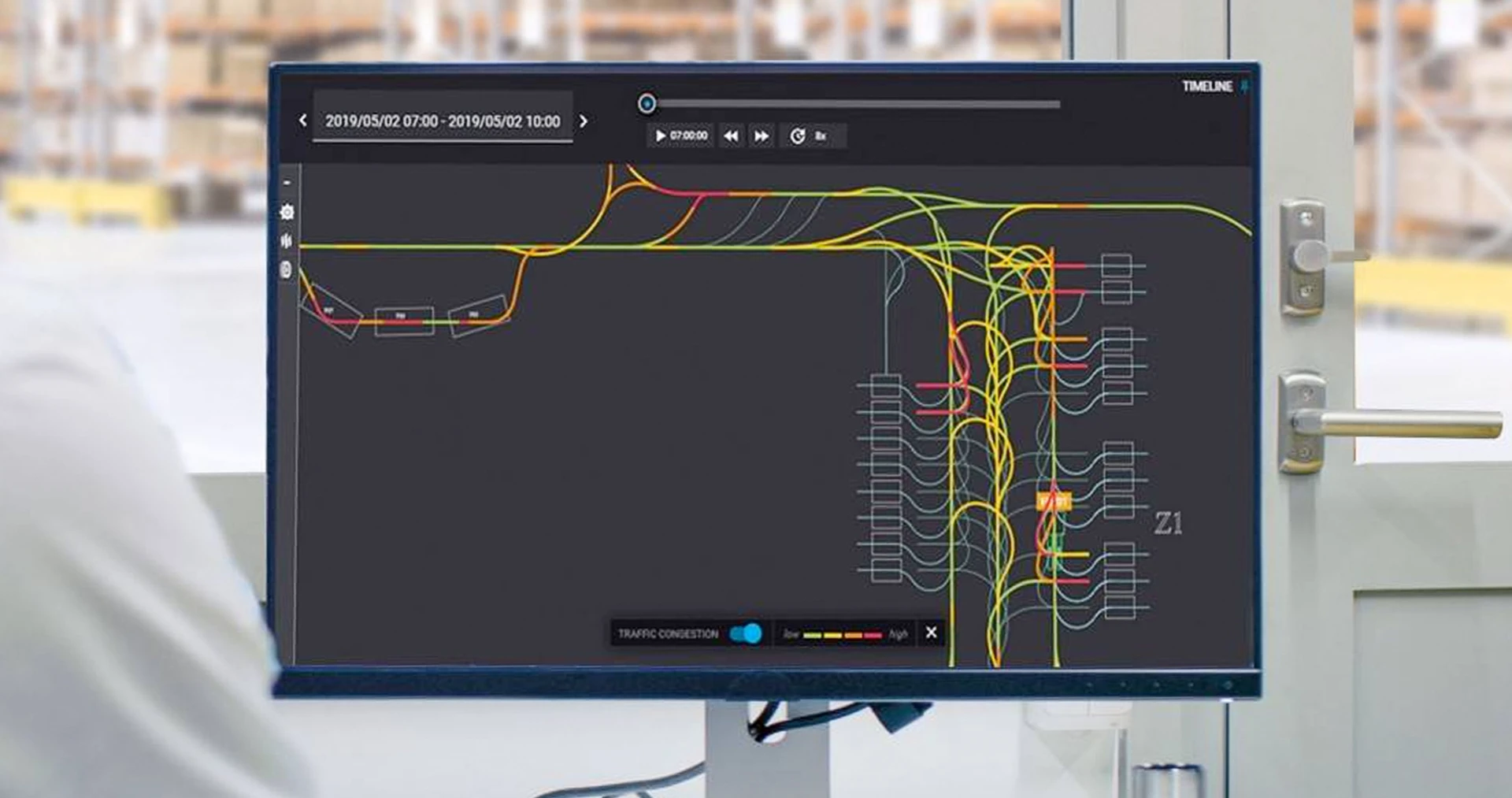

Vehicle guidance system

The transport or vehicle guidance system determines "which truck has to go where to transport something". It distributes and optimises the transport tasks, taking into account various criteria such as connecting trips, order priorities and transport order types - either manually or semi- or fully-automated. For automated systems, it can be supplemented with the iGo insights monitoring software to observe and analyse transport movements.

The information system

Captures all order data in real time and provides the relevant logistics key figures clearly for extensive analysis options.

iGo insights

iGo insights uses the principle of machine learning to improve the performance of your automated system. All data collected by the AGV control system over a long period of time is uploaded to the cloud for evaluation and can be accessed online via the encrypted web portal.

From the wealth of process information collected, correlations can be filtered and concrete recommendations for action can be derived, thus optimising the availability and performance of your system.

iGo pilot navigation interface

During storage and retrieval, the vehicle accesses the exact coordinates of the storage locations. Depending on the technical status of the EDP system (alternatively: ERP system) and the desired level of comfort, the manual input of the target coordinates, the scanning via barcode scanner or the transmission of the target data from the warehouse management system can be selected for the connection of iGo pilot navigation.