Electric forklift truck RXE 10 – 16C

The zippy one

- Load capacity 1600 kg

- Rated lift 6810 mm

- Speed 12 km/h

Great in the smallest of spaces

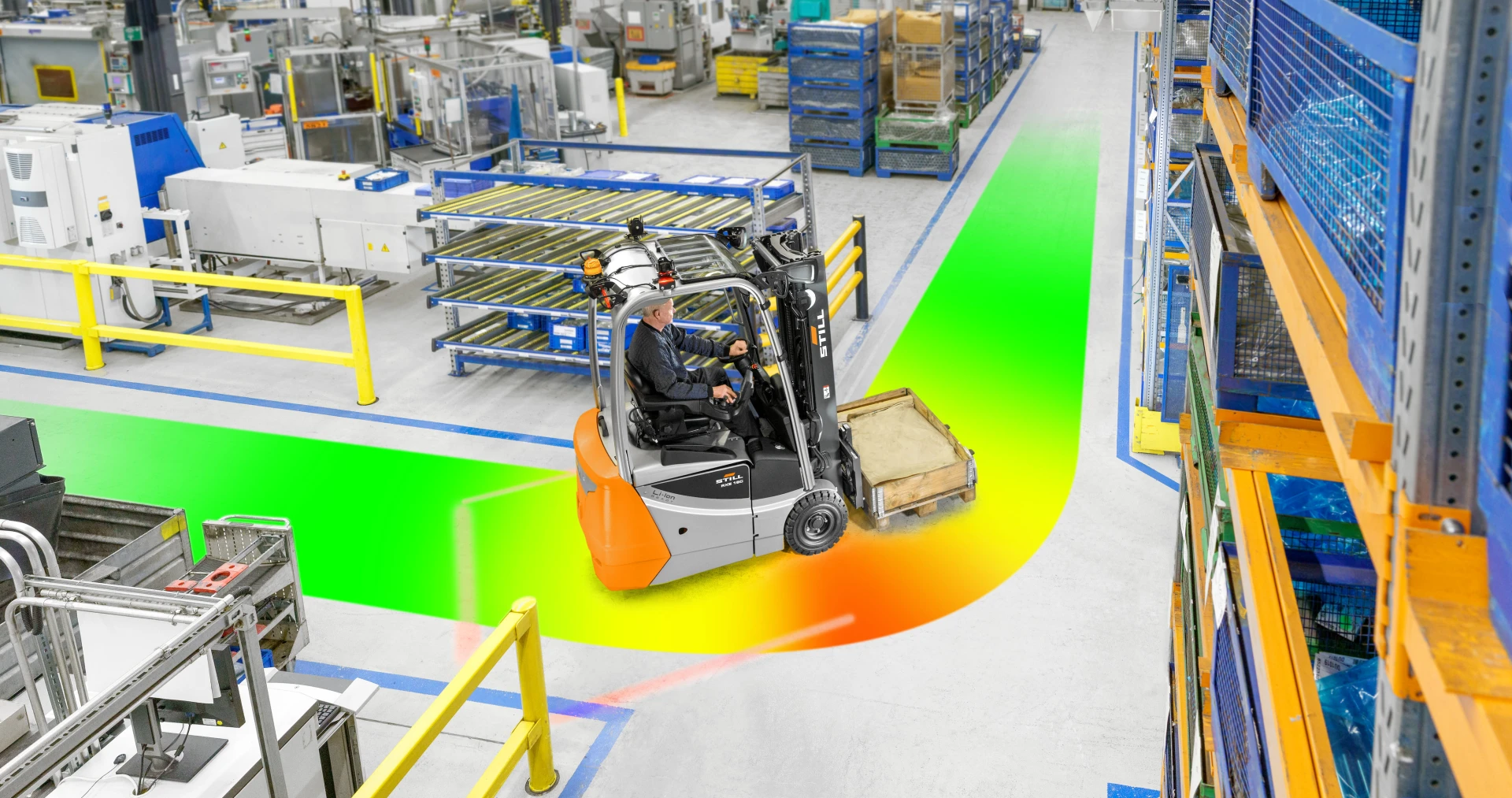

Turn it any way you want, the RXE 10–16C simply fits. Always. The youngest and smallest member of the electrifying STILL electric forklift truck family is one of the greatest in terms of performance: compact as it is, it shines with a perfect balance of driving comfort, manoeuvrability and safety – even when things get really tight. Be it in HGVs, containers or narrow aisles, the RXE 10–16C is incomparably efficient and agile in the smallest of spaces thanks to its compact dimensions and sensitive steering. And that is precisely why it is so versatile.

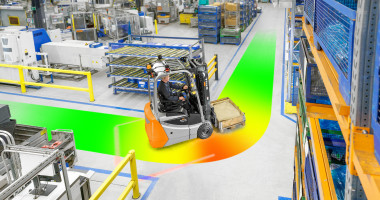

Whether it is in the food industry, at logistics service providers, in production supply or in joint warehouses of large retailers, the compact three-wheel counterbalanced forklift truck inspires as an efficient helper for loading and unloading HGVs or containers as well as for transporting pallets in the warehouse. With a top speed of 12.5 km/h, it gets a lot done very quickly. And to ensure that not a single moment of its electrifying dynamics is lost for safety reasons, it is equipped with the proven Curve Speed Control as standard. This keeps you safely on track at all times – even in the tightest of curves. So when it comes to moving 1.0 to 1.6 tonnes in a space-saving way, the RXE 10-16C is the perfect choice! With its wide range of equipment options and assistance systems, it is also an attractive upgrade from the high lift stackers, with increased comfort and added safety. All this makes it the perfect successor to the legendary STILL RX 50, one of the best-selling electric forklift trucks in its class ever. Proof that the RXE 10–16C fits the bill. Always.

The "Simply Efficent" factors: Performance attributes as a measure of economic efficiency

Simply easy

Familiar, intuitive handling

thanks to the uniform operating concept across the RX electric forklift truck family

Relevant information and performance functions

clearly available in STILL Easy Control Bordcomputer

Perfection in confined spaces:

compact truck dimensions and extremely high manoeuvrability allow for working in narrow aisles

Always available

thanks to the lateral quick-charge access for optional lithium-ion batteries

Simply powerful

Powerful and reliable

thanks to maintenance-free rotary current drive in 24 V technology

Impressive productivity

thanks to a lifting capacity of up to 1.6 tonnes with a load centre of 500 mm

Effective material handling

thanks to a maximum driving speed of 12 km/h when laden

Supports the driver

with smart assistance functions

Ready at all times

thanks to the optional lithium-ion technology

Simply safe

Safe and precise handling:

high-precision hydraulics and agile driving dynamics

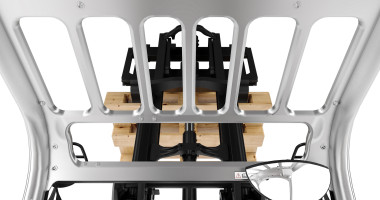

Optimal all-round visibility

thanks to slim mast and visibility-optimised protected roof bars

Systematic safety

thanks to the (optional) daily pre-shift check in the display

Maximum safety at work

thanks to individually configurable equipment options – from indicators to Safety Light 4Plus safety lighting and curve speed control

Safe load handling

thanks to numerous assistance functions such as lift height display and overload detection

Simply flexible

Individual control options for optimal driver comfort:

multi-lever, mini-lever, Fingertip or Joystick 4Plus

Perfect for any application

thanks to a flexible portfolio with a wide range of equipment options

Flexible use in forklift truck fleets thanks to the uniform operating concept across the RX series:

drivers can switch between RXE 10–16C, RX 20 and RX 60 easily and without training time

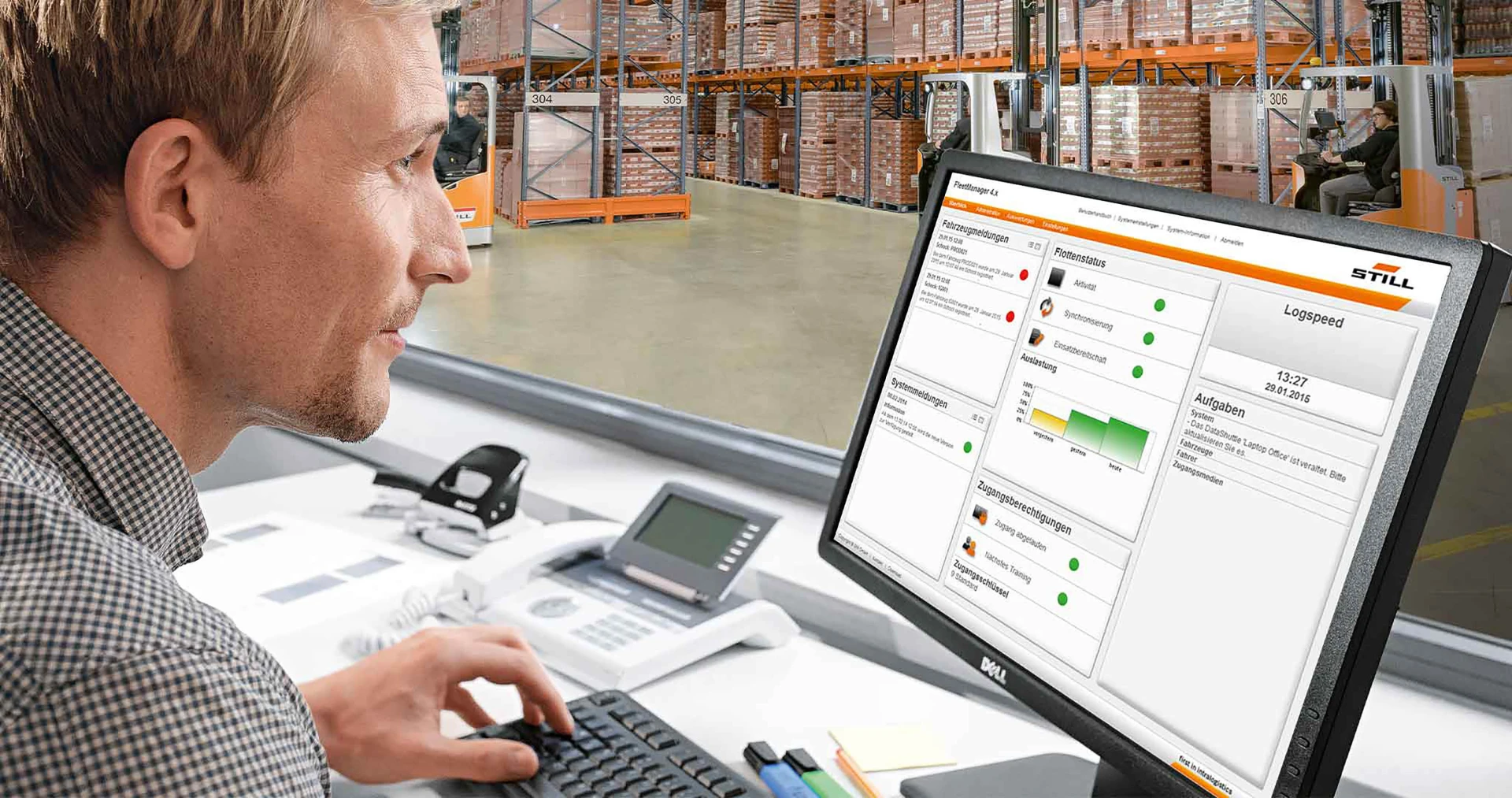

Simply connected

Can be optimally networked via an optional interface,

which allows for uncomplicated integration into fleet management systems such as STILL neXXt fleet

Controlled use and protection against incorrect operation

thanks to optional access control

STILL Li-Ion Technology inside

The perfectly harmonised power system for reducing operating costs and increased truck availability.

More about STILL Li-Ion TechnologyEquipment options

Sharpening all senses: we can support you with our wide range of smart driver assistance systems and functions which will make your day-to-day work significantly easier. You will be able to drive in a safer, more comfortable, efficient and fatigue-free manner – in every driving situation.

Perfect addition to the STILL SafetyLight

The STILL warning zone light projects two strips of light to the left and right of the forklift truck. The optional illumination equipment serves as a visual warning for pedestrians and other drivers in the vicinity by projecting luminescent strips on the hall floor at the sides of the forklift truck.

The STILL Warning Zone Light Plus projects a semi-circle around the rear of the truck. This also increases awareness of the truck and marks a typical danger zone when approaching. This reduces the risk of pedestrian injury.

The STILL Warning Zone Light and the STILL Warning Zone Light Plus therefore perfectly complement the STILL Safety Light, which projects a blue cone of light in the front of the truck in the direction of driving.

Keeping the goods in place: the load backrest stabilises the transported goods at the fork carriage back so that they can be securely transported from A to B.

Buckled up? If not, the seat belt control ensures that the driving speed is automatically reduced. In cab trucks, the system only engages when the cab door is open.

With Dynamic Load Control, you can ensure smooth, safe and efficient lifting operations by precisely detecting loads and lifting heights and automatically adjusting the hydraulics. Depending on the vehicle, different variants of the DLC are available to you. Increase productivity and safety - for fewer risks and optimum performance in daily use!

Learn more

Fulfills lifting height requirements at the push of a button:

Whether the racks are to be filled or emptied - you know the game: look closely, extend the mast, maintain concentrated eye contact, stop the mast, readjust if necessary. Several times. In every shift. On every day. Now imagine that you could leave your sense of proportion behind. Imagine you could just press a button and wait for the forks to float to exactly the right height and stop there automatically. Imagine: You can. With the STILL lift limiter, the forks automatically stop at up to three programmable intermediate lift heights. And to ensure that your profitability, but not your trucks, goes through the roof, the maximum lift height can also be permanently programmed.

Learn moreWith the help of the optional LED lift height sensor (standard on the FM-X), the lift height display ensures maximum precision from the very first millimetre. This means that operators always know the height of the fork tips and can navigate precisely to avoid touching the rack when picking up the pallet. The system works with a repeatability of less than +/- 5 mm and the lift height is permanently shown to the drivers on the display.

Learn more

Autostop before ground contact:

When forks hit the ground, it's not pleasant for the ears, the floor or the forklift. But on the other hand, would it not be very pleasant if this would not happen in the first place? That's exactly why we developed the electric fork wear protection for you. When the assistance system is activated, it ensures that the forks cannot touch the ground during lowering. Shortly before that, they stop automatically - exactly so that you can thread them perfectly into the pallet. Forks dragging on the ground due to accidental startup in the lowered state are also a thing of the past.

Learn moreQuiet lifting!

Strength lies in peace - this now also applies to your forklift trucks. Because the Silent Lift assistance system puts an end to noise during lifting and lowering operations. Smooth lift transitions, smooth storage and retrieval on the top shelf level, and an automatic stop of the forks before they hit the floor - all this promises you heavenly peace and quiet even when lifting and lowering the heaviest loads.

Learn moreForks up, speed down:

More safety, less product breakage and ensuring proper vehicle use - these are the benefits offered by the Speed Reduction assistance system when the fork carriage is raised. As soon as the forks reach a height of 500 mm (or another defined threshold), the speed of the vehicle is automatically reduced. Even if a driver forgets that he should not drive with the load raised, the assistance system slows him down, guaranteeing safe handling of the load and vehicle.

Learn more|

Model

|

Maximum capacity (kg)

|

Maximum lift height (mm)

|

Travel speed (km/h)

|

Battery voltage (V)

|

|---|---|---|---|---|

| RXE 10 | 1.000 | 5.610 | 12 | 24 |

| RXE 13 | 1.300 | 6.060 | 12 | 24 |

| RXE 15 | 1.500 | 6.810 | 12 | 24 |

| RXE 16C | 1.600 | 6.810 | 12 | 24 |

Downloads

The document provided for download is the updated version of the operating instructions for the standard truck. It does not include descriptions of customer options (Customer Option). For a concrete truck, please request the respective specific manual according to the serial number and the year of production from the STILL spare parts service.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday between 8 a.m. and 6 p.m

Use the contact form

Write to us – we will get back to you within 24 hours