Lithium-ion batteries – are they really worth it?

Over the last few years, new types of batteries have started coming out for powering electric forklift trucks. E-trucks, pallet trucks, pallet stackers, reach trucks and order pickers can now all be powered with Lithium-ion technology.

Although they cost more than normal batteries, Lithium-ion batteries have dropped in cost faster than experts had forecast, with the price falling by 50% since 2011, something which hadn’t been anticipated prior to 2020.

Lithium-ion (Li-ion) batteries are therefore more accessible than ever before, but it’s still worth asking whether it’s an investment that will pay off.

Lithium-ion (Li-ion) batteries are therefore more accessible than ever before, but it’s still worth asking whether it’s an investment that will pay off. The Material Handling Blog supports you in your day to day material handling operations, and helps you to make the right choices for maximum productivity. Read this article to learn more about the advantages of Lithium-ion batteries and when they’re the best fit.

What is a Lithium-ion battery?

Li-ion batteries use lithium iron phosphate, or LFP-based technology, which has proven its effectiveness time and again. A significant advantage of this technology is that it maintains optimal efficiency regardless of operating temperature, even in cold storage warehouses.

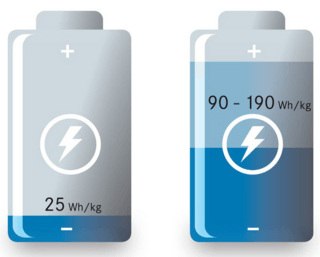

Lithium-ion batteries also have a far higher energy density than that of a lead-acid battery:

Record productivity with Lithium-ion technology

The first key advantage of Li-ion batteries is a dramatic boost in productivity. The batteries are designed for intensive use; for example they can be used over the course of two shifts to keep a forklift truck in continuous service without changing the battery. This saves time and is more ergonomic for your employees, who no longer need to handle the batteries when they run out of charge.

However, intensive use isn't the only benefit of Lithium-ion batteries. They also allow for opportunity charging or ad hoc charges. This is particularly useful for applications where they are not in constant use. The batteries can easily be charged back up, as you only need a wall socket for opportunity charging. Because they have high energy density, Li-ion batteries are more compact than other types.

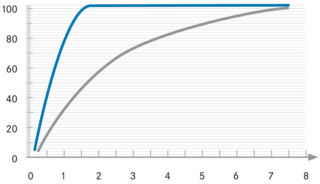

- After 40 minutes of charging, they will regain 60% of their total charge.

- After an hour of charging, they will regain their full charge.

In summary, Li-ion batteries are particularly well suited to intensive use, they are compatible with opportunity charging, and they also charge very quickly. Together these advantages spell uninterrupted productivity.

Unprecedented energy efficiency with Li-ion technology

The second key advantage of Lithium-ion batteries is their reduced energy consumption. In fact Li-ion batteries consume an average of 30% less energy than more traditional lead-acid batteries. It’s not just better for the planet, it’s better for your wallet too!

Zero-maintenance batteries

Of course, it’s important to bear in mind that buying a Li-ion battery for your forklift truck will cost more than buying a traditional one. However, one thing you can be sure of is that you won't have any maintenance costs to worry about! This is because Lithium-ion batteries require no maintenance.

Lithium-ion battery life well above the average

The last key advantage of Li-ion batteries is that they are guaranteed for at least 2500 charge cycles. Depending on how they’re used, they can last twice this long, or even more! This gives them a useful life many times greater than a lead-acid battery.

Case study for Lithium-ion batteries

Li-ion battery technology brings with it a new way of thinking about ‘energy’ and ‘flows’ within a warehouse. But what does this mean in concrete terms? The Material Handling Blog would like to put forward a case study from the H. & J. Brüggen KG group, which converted all 66 of its forklift trucks (pallet trucks, E-trucks and pallet stackers) to Li-ion power in 2016.

What were the group’s main objectives? They wanted to harness potential productivity growth and reduce operating costs.

So how do you increase efficiency while decreasing costs? It turns out all you need is transparent and predictable costs (provided via a leasing arrangement which included a package of services), high availability combined with maximum flexibility in usage, shorter battery charge times, and an online fleet management tool.

Using this model, the group were able to reduce the size of their fleet by 23.8% thanks to Li-ion technology.

Productivity and power: The superior performance offered by Li-ion batteries makes them perfect for any application where traditional lead-acid technology would quickly reach its limits. This includes applications where more power is needed, or where batteries need to be used over several shifts without charging. Pound for pound, the Li-ion battery has twice the power of the lead-acid battery, which means fewer battery changes and a leaner infrastructure.

Savings: Li-ion batteries also remove the need for maintenance of the electrolyte, making them practically maintenance-free.

Ergonomics: Changing to Li-ion batteries means that employees have an easier and more comfortable time as they go about their work. Before, they’d have to remove the empty batteries from the forklift truck, connect them up to a dedicated recharging station, and then leave them for over six hours to recharge, checking up on the level of distilled water and so on. Now, all they need to do is recharge them using the socket on the outside.

At Brüggen, this change has significantly increased the availability of their forklift trucks, which has had a very positive impact both in terms of cost and efficiency.

„We have a handful of forklift trucks that run around the clock, and these are essential to our logistical and production operations. The new batteries can be recharged at any time, just like a smartphone, and only need a few minutes of charge.“

In conclusion, if you’re debating a switch to Lithium-ion batteries, you should first analyse how you use your forklift trucks in order to decide whether it’s worth it or not. Regardless of what answer you come to, you can count on us to help you with your decision!

Contact request

Subscribe to the Newsletter !

Always up to date with STILL: Subscribe to the STILL newsletter and we will inform you regularly about interesting industry topics.