Stability monitoring

Safety solutions

Avoid unstable driving or load situations.

Ensure your storage fleet keeps its wheels on the ground. Assistance systems and safety features help your operators to avoid dangerous driving or load situations.

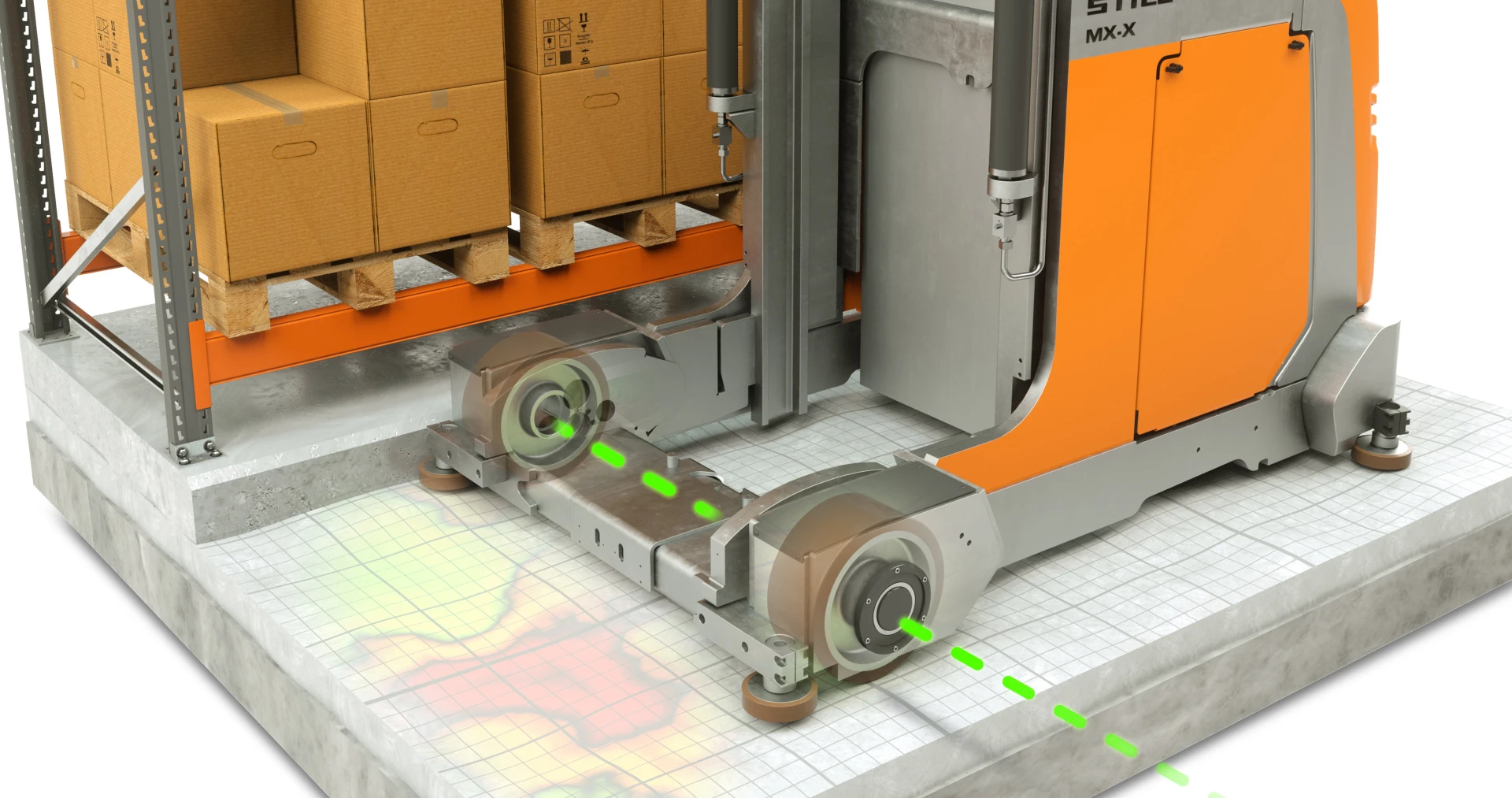

Active Floor Compensation (AFC)

So that everything runs smoothly – even if the floor doesn't

Active Floor Compensation (AFC) for STILL VNA trucks MX-X l – maximum performance even on uneven floors.

With the assistance system for the MX-X Very Narrow Aisle Truck, we offer a genuine alternative to reconditioning the warehouse floor. The system identifies any uneven surfaces in the load wheels’ path and compensates for them in real time. This ensures that the truck frame always remains horizontal and the mast vertical. The AFC system – the only one of its kind on the market – has ultra-fast processors which allow it to react instantaneously, even when travelling at top speeds. In contrast to passive systems that only have a dampening effect, this system actively prevents vibrations before they occur.

Please fill out the form below. We will get back to you as soon as possible.

Curve Speed Control

Automatic speed adjustment for curves

The speed limiter controlled by steering angle reduces possible damage to goods by adapting to an appropriate cornering speed. This assistance function is available for various forklift trucks and warehouse technology devices, and regulates the driving speed automatically according to the steering angle. In other words, the driver doesn’t need to worry about speed when cornering. The truck automatically decelerates precisely as much as necessary for the operator to drive as safely but as quickly as possible.

Solution available for following trucks

Dynamic Load Control

With Dynamic Load Control, you can ensure smooth, safe and efficient lifting operations by precisely detecting loads and lifting heights and automatically adjusting the hydraulics. Depending on the vehicle, different variants of the DLC are available to you. Increase productivity and safety - for fewer risks and optimum performance in daily use!

Solution available for following trucks

Active Load Stabilisation (ALS)

No wobble here

The FM-X is always more than just a fork ahead of the rest. Thanks to Active Load Stabilising (ALS) you can be dealing with the next goods transport while others have to wait for the mask to stop vibrating. An automatic equalising pulse provides a fast and effective way of stopping the vibrations from occurring at great heights, reducing the waiting time at the shelf by up to 80%. The result is a significant increase in turnaround speed.

Solution available for following trucks

Lift height display

With the help of the optional LED lift height sensor (standard on the FM-X), the lift height display ensures maximum precision from the very first millimetre. This means that operators always know the height of the fork tips and can navigate precisely to avoid touching the rack when picking up the pallet. The system works with a repeatability of less than +/- 5 mm and the lift height is permanently shown to the drivers on the display.

Solution available for following trucks

Forks up, speed down:

More safety, less product breakage and ensuring proper vehicle use - these are the benefits offered by the Speed Reduction assistance system when the fork carriage is raised. As soon as the forks reach a height of 500 mm (or another defined threshold), the speed of the vehicle is automatically reduced. Even if a driver forgets that he should not drive with the load raised, the assistance system slows him down, guaranteeing safe handling of the load and vehicle.

In addition to the lift height display, there is a range of lift height pre-selection systems available for the STILL FM-X reach truck. Manual lift height selection is available as standard. The Easy Target and Easy Target Plus systems are available as options.

Easy Target enables fast and precise positioning of the forks at the desired shelf levels, without the need for manual height corrections. This increases safety for both the driver and the goods. Up to eight areas, each with 20 levels, can be programmed. From 150 kg, the forklift truck is able to independently determine whether the operator wishes to store or retrieve loads and thus consider the pallet free lift accordingly. Another option available is Easy Target Plus, which also ensures that the fork tilt is in the neutral position. How you benefit: Individual customisation to suit all warehouse conditions, high degree of safety for the driver and the goods, and guided operation via the display assistant – also, for less experienced drivers, the shelf level can be selected in a matter of seconds.

Overload excluded:

If the forklift can still handle this load? A question that can quickly lead to injuries, vehicle or goods damage. Fortunately, there is overload detection. The system monitors the weight of the load and any attachments and always gives you a safe and clear answer. What's more, if the total weight exceeds the rated capacity or the set maximum load, the system actively intervenes and reduces the lifting speed. If the threshold value is exceeded by more than 10 percent, the lifting function is completely blocked. This means that the driver, vehicle and goods are always optimally protected.

More safety, more comfort: the optional positioning laser projects the fork height with a green laser line on the carrier, thus serving as a visual extension of the fork. This facilitates orientation when storing and retrieving goods, as well as increasing both the handling capacity and the degree of safety. The positioning laser can be easily switched on and off at the touch of a button and poses no threat to the naked eye.

Stability at all times: the optional load capacity display shows the user the current lift height and the associated residual load capacity at all times. The load capacities and lift heights are displayed on the coloured signs attached directly to the mast.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday between 8 a.m. and 6 p.m

Use the contact form

Write to us – we will get back to you within 24 hours