Operation and control of automated tugger trains

Partially to fully automated concepts

Automated tugger trains are a type of driverless transport system (DTS). They consist of a towing truck and two to four trailers (frames). Travel and load handling may be manual, or semi- or fully automatic. Automated tugger trains are offered with a dual-use option. Different types of control are available as well as various automation variants and technologies that can be used.

When designing the automated tugger train system, the question of how the system can be optimally planned for the specific application needs to be answered. The focus here is on standardising automated processes, loading and unloading as well as a flexible production supply and the structure of the route planning. While control via kanban is possible for the static route, special software is required for the dynamic route.

Different solutions are also possible for navigation, load handling and transport management:

1. Navigation

Magnetic track or optical navigation

- Guidance via magnetic track or lines on the ground

- Stations can be mapped with sensors

- Good positioning accuracy

- Modification is not possible without significant time and effort

Laser navigation

- Triangulation using established reference points, such as building features or reflectors

- The reflectors are placed in the hall and their position is recorded with millimetre precision in the layout. A laser scanner positioned on the vehicle head identifies the reflectors and can thus determine its position with a high degree of accuracy (+/- 1 cm). This form of navigation is required for automated load handling.

- Complex requirements due to the need to define the stations

Contour navigation

- No need to install reflectors in the hall

- Automated tugger train uses the building structure for orientation (walls, windows, racks etc.)

- With a precision of +/- 8 cm, contour navigation is less precise than laser navigation using reflectors for orientation

- Not suitable for automated load handling

- Can be used with manual load handling

- Complex requirements due to the need to define the stations

2. Load handling

Load handling comprises loading and unloading of goods. It can be combined with manual and automated travel.

Manual

- Loading and unloading of the frames and trolleys by logistics employees

Internal automated load handling:

- The frame is loaded and unloaded (triggered manually or by the system) by a device integrated into the frame (e.g. telescopic forks or roller tracks); the process is controlled and initiated by the driver.

External automated load handling:

- Loading and unloading of the trolleys in the frame by external systems such as a pallet gripper

Combined internal and external automated load handling:

- All process steps are automated and controlled entirely by a higher-level control system. This is often the case in SLC handling in which, for example, shooter systems automatically load full load carriers onto the rack trolley levels when they come into contact with the transport system while also removing empty containers.

3. Transport management

STILL offers suitable software to go along with its tugger train solutions with automated tractors. A driverless transport system (DTS) includes a DTS master controller, which controls the trucks contained in the system. The master controller used by STILL is a piece of software that helps the operator optimise the drive mode. It connects a general host system, such as a warehouse control system (WCS) or a warehouse management system (WMS), and the deployed trucks. The software can, for example:

- select the right truck for material transport

- manage the battery and maintenance functions for all trucks

- prevent accidents during travel and intervene in critical situations (e.g. obstacles on the track)

- manage traffic in a facility as a stand-alone system

- prioritise orders

- ensure goods tracking from the delivery point up to the point of use in real time

Automated solutions in the form of driverless transport systems have been in use for some time in the intralogistics sector and have already become firmly established in many companies.

The following applications exist when handling large carriers (e.g. pallets, grid boxes) with regard to loading and transport:

Application A

Automated material transport in a VNA warehouse

Task: automatic storage and retrieval in the buffer storage area (VNA warehouse) as well as the automatic supply of the picking area in the European distribution centre of a furniture store.

The automated trucks: The STILL MX-X VNA truck automatically retrieves goods and brings material to the transfer station at the rack, while an automated STILL FM-X reach truck is used for the long-distance transport.

Application B

Automated material transport in a channel and wide-aisle warehouse

Task: Automatic implementation of the shuttle trucks in a channel warehouse and long-distance transport of the retrieved big bags to be transferred to a materials handling system for onward transport to the point of use of a speciality chemicals company.

The automated trucks: Automated reach trucks automatically and precisely place the shuttles in the correct channels and transport the big bags to be retrieved to the transfer station of the materials handling system, which allows the big bags to be transported to the pumping machines for further processing. The reach trucks also dispose of the empty pallets.

Application C

Automated material transport with mobile and stationary transport systems

Task: Fully automatic pallet transport with mobile and stationary transport systems from production through to storage and retrieval as well as the just-in-sequence route provision for a fruit juice producer.

The automation: A sophisticated materials handling concept (chain conveyors and transfer trolleys) connects the production area with the logistics centre and ensures the efficient use of the non-square building. Automated MX-Q VNA trucks take the goods from the materials handling system and are responsible for their storage and retrieval. The automated EGV-S high lift pallet trucks arrange the trips.

Driverless transport systems can be used for more than just large carriers. Small load carriers (SCs) are generally combined to form packaging units and are transported on mobile racks (trolleys with a rack structure).

In general, the handling of large carriers or small load carriers in traditional automation is structured as follows:

the link between the truck and loading is common to both.

There is a loading point, a truck and an unloading point.

As a result, the following three process steps are required:

- Loading

- Transport

- Unloading

Loading, transport and delivery can take place automatically; only the loading and delivery point differ.

Requirements analysis

Our offer for the joint preparation of the concept and requirements specification

We answer the following question together with you: What potential for automation can be uncovered in your warehouse and production logistics – and what does your automation system ultimately have to achieve?

Result: an individual requirements specification based on your needs, which you can use for your invitation to tender. The requirements specification is the technical basis for your automation concept.

Whether load handling takes place manually or automatically primarily depends on the spatial conditions at the production area, where the area must be considered in relation to the routes. The requirements concerning the different control variants also play an important role, as do the available interfaces between production and production supply (e.g. in supermarkets).

Manual load handling

- Loading and unloading of frame and trolleys by the operator

- Enough space for the frame, trolley and operator

- Unloading point does not have to be directly accessible

- The route is similar to that of a conventional industrial truck

- Can be combined with manual or automated travel

Automated load handling

- The unloading point must be directly next to the train

- Space requirement of approx. 1.5 times the train length per unloading point

- For external load handling, equipment with the same technology as source (or manual)

- Route can be significantly narrower as the space for the production worker is no longer required

- Can be combined with manual or automated travel

Controls

Different controls are available for automated tugger train solutions. In the case of dynamic route navigation, a connection to the customer’s warehouse management system is required. The STILL control software E´tricc® takes control of tasks and services such as transport management and transport order preparation, transport monitoring, visualisation, diagnostics and host interfaces. Static route navigation only requires a small amount of software; it can also be controlled entirely with kanban.

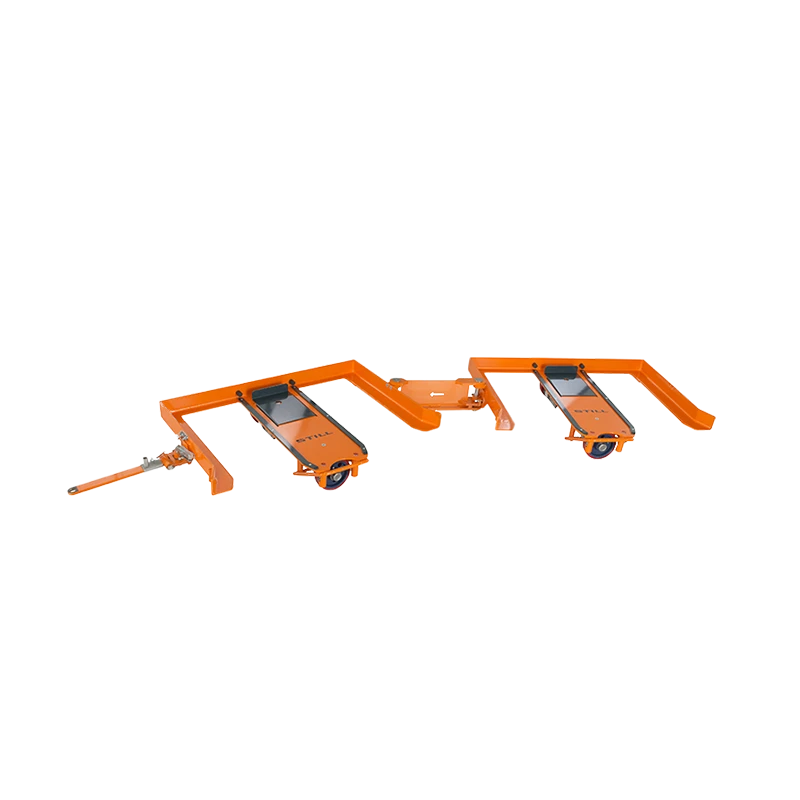

There are several variants of automated tugger trains. What is common to all is their setup: they generally consist of a tractor and, ideally, four trailers. The loading and delivery point do not necessarily have to be identical. The transport process involves different steps depending on the degree of automation:

- Loading: this can be done manually or automatically

- Transport: transport is either automated or manual

- Unloading: goods are transferred manually or automatically

Several levels of automation are available for selection with regard to travel and load handling. Which of the different versions will work best for your specific operation needs to be individually defined following a prior, intensive analysis by an expert.

1. Automated travel with manual load handling

2. Manual travel with automated load handling

3. Automatic travel with automated load handling

For automated travel, a manual tractor is fitted with an automation kit. This contains all the components needed for automation, such as laser scanners, personal protective equipment, WiFi and software interfaces. An automated tugger train is path-controlled, meaning that it travels to the destination along previously defined paths.

Automated travel with manual load handling:

- automated tractor with manual frame (E-/B-/C-frame)

- automated travel to the stations with automatic stop at every station

Option 1:

- Automated travel from station to station, irrespective of whether an activity does or does not need to be performed. The operator manually pushes a button to send the train to the next station.

- Alternatively, the truck can also be driven manually between the individual stations (dual use)

- Advantage: a manual kanban card system can continue to be used for the subsequent delivery of material

or option 2:

- requires complete system control of the tugger train with traffic management, order management and interface to the warehouse management system. Automated travel to the next station where something needs to be loaded or unloaded. Manual travel release at the station by the worker after the frames have been loaded or unloaded, onward travel to next station where something needs to be loaded or unloaded.

Manual travel with automated load handling:

- manual tractor with automated frame (E-/C-frame)

- manual travel to the stations

- the automated loading and unloading of the frame is controlled by the driver

Automatic travel with automated load handling:

- automated tractor with automated frame (E-/C-frame)

- automated travel to the stations

- automated unloading of the frame is then initiated by the system

For an automated tugger train (especially during automated load handling) more space is required with regard to the length of the train. It must be possible to approach unloading points so that the tugger train is positioned entirely parallel to the unloading point. The implementation of a tugger train essentially connects supply to and removal from production. Automated trains therefore have a specific route planning requirement.

A driverless transport system (DTS) consists of one or more driverless transport trucks (DTT), a master controller, position recording and data transmission equipment, infrastructure detection equipment and various peripheral equipment. Their main task is the automated transport of material. Driverless transport systems are also used for service tasks, such as monitoring, cleaning, mobile information and visitor guidance.

A driverless tugger train is a combination of a driverless industrial truck (automated tractor) and a variable number of trailers.

In summary: Numerous variants of automated tugger train solutions exist with regard to travel, load handling and control and you are sure to find a solution that fits perfectly to your requirements.

We use our expertise to help you analyse your processes and identify automation potentials in order to set your company up for the future.

Following your request, we would be pleased to send you a free download of our white paper as an introduction to automated tugger trains.

Rückruf vereinbaren

Glossary

Master controller

The master controller controls all of the trucks operating in the system. It helps the operator continuously optimise the operation. It connects a general host system, such as a warehouse control system (WCS) or a warehouse management system (WMS), and the deployed trucks.

Tugger train

Tugger trains are a means of transport for ground-level material transport. They are generally made up of a towing truck and one or more trailers, on which carriers are placed. Both the driving and load handling can be carried out either manually or partly or fully automatically.

Driverless transport systems

Driverless transport systems (DTS) are defined as follows according to VDI Guideline 2510: They consist of various components that have to work together in a precisely controlled and coordinated manner. These include a master controller, equipment for detecting and recording the location and position of the transport trucks, equipment for transmitting data to and from the trucks in the DTS, infrastructure and peripheral equipment (e.g. charging stations).

Dual use

Driverless transport systems with a dual-use function can be used in automatic mode as well as with manual control functions.

Kanban

Kanban is a technique for stock management and production control. It is based on the ‘pull’ principle and involves the consumer taking the material required for production from the supplier. Once a defined kanban quantity has been used up, the consumer sends the supplier a ‘kanban card’ as a prompt to provide the kanban quantity again.