The safety of automated solutions from STILL

How safe are automated tugger trains?

The performance and the areas of application for driverless transport systems (DTS) have increased in recent years. Automated systems are also increasingly being used in the intralogistics sector, including automated tugger trains. However, the topic of ‘automation’ is also currently associated with user concerns, especially in relation to safety aspects. A number of smart software solutions promise a very high level of safety.

All of our driverless transport systems have been thoroughly tried and tested many times over. Like all STILL equipment, our automated tugger trains also use our established sensor technology, which ensures the highest level of safety for the operator, product and equipment at all times.

Requirements analysis

Our offer for the joint preparation of the concept and requirements specification

We answer the following question together with you: What potential for automation can be uncovered in your warehouse and production logistics – and what does your automation system ultimately have to achieve?

Result: an individual requirements specification based on your needs, which you can use for your invitation to tender. The requirements specification is the technical basis for your automation concept.

Driverless transport systems are subject to high safety requirements. A STILL driverless transport truck is therefore equipped with various safety components that take account of these requirements and automatically, or via manual activation, stop the truck in potentially dangerous situations.

Our trucks also have safety components that provide alerts for different truck movements, such as turns or the raising and lowering of loads. These safety features make the driverless transport truck an extremely safe means of transport, especially compared to conventional forklift trucks.

All safety components installed on the DTS comply with European standard EN 1525.

Trucks are equipped with different safety features depending on the type of truck, the area of application and individual system requirements.

These include:

- safety laser scanners for personal protection

- emergency stop button

- visual warning signals

- acoustic warning signals

Safety laser scanners

The safety of the truck is ensured by two safety laser scanners. These sensors were developed to identify unexpected objects within the horizontal scanner field. The laser scanner has two safety fields, a protective field and a warning field.

The warning field is longer and wider than the protective field. When an object is detected, the truck reduces its travel speed to below normal walking speed. If the object is detected in the protective field, the safety relay triggers an emergency stop. The safety field is located at a height of 150–160 mm. Once the object has been removed from the scanner area or the person has moved away, the truck automatically resumes operation.

Emergency stop button

The emergency stop button allows the operator to manually stop the truck in an emergency.

Visual and acoustic warning signals

An acoustic warning signal sounds when the truck moves. The warning lights and indicators indicate the truck movements, such as forward travel, turns, load handling or errors.

Besides the general safety provisions, which employees must observe when handling equipment and trucks in day-to-day operations, additional rules apply for the use of automated solutions such as driverless transport systems. For instance, protective measures must be implemented for possible crush and shear points, and emergency stop devices may need to be provided during automatic lowering and raising processes and the automated loading and unloading processes.

General safety provisions may include the following:

- the tractors may only be used by instructed and authorised employees with an appropriate driving licence and current G25 check-up

- safety gloves must be worn during loading and unloading (manual load handling)

Semi-automated and fully automated tugger train concepts are already designed with numerous automatic processes, so that they relieve the operator of the burden of performing many of the safety requirements themselves. For example, they are fitted with a person recognition system and a start-up warning device as well as a very slow automatic acceleration to protect the trailers, all of which are mandatory for driverless systems pursuant to DIN EN 1525.

The following additional safety rules apply when using automated tugger trains:

- only employees who have received intensive training in the handling of automated tugger trains may operate the equipment

- employees must have received training in the use of warehouse management systems and the relevant software

In summary: Thanks to sophisticated safety systems and functions, automated tugger trains are smart assistants in production logistics and offer a very high level of safety.

We use our expertise to help you analyse your processes and identify automation potentials in order to set your company up for the future.

Following your request, we would be pleased to send you a free download of our white paper as an introduction to automated tugger trains.

Rückruf vereinbaren

Glossary

Master controller

The master controller controls all of the trucks operating in the system. It helps the operator continuously optimise the operation. It connects a general host system, such as a warehouse control system (WCS) or a warehouse management system (WMS), and the deployed trucks.

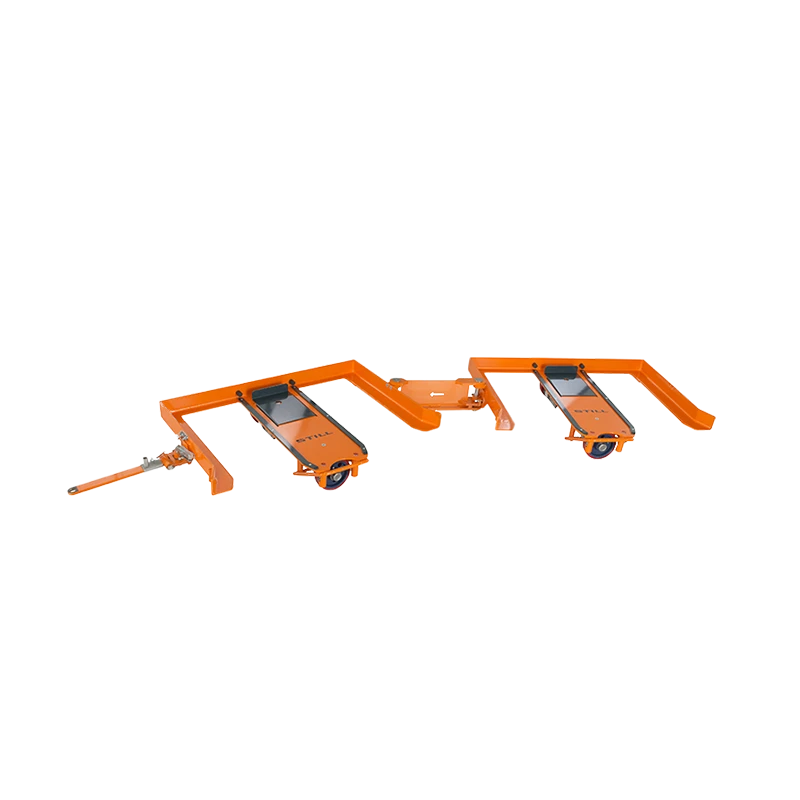

Tugger train

Tugger trains are a means of transport for ground-level material transport. They are generally made up of a towing truck and one or more trailers, on which carriers are placed. Both the driving and load handling can be carried out either manually or partly or fully automatically.

Driverless transport systems

Driverless transport systems (DTS) are defined as follows according to VDI Guideline 2510: They consist of various components that have to work together in a precisely controlled and coordinated manner. These include a master controller, equipment for detecting and recording the location and position of the transport trucks, equipment for transmitting data to and from the trucks in the DTS, infrastructure and peripheral equipment (e.g. charging stations).

Dual use

Driverless transport systems with a dual-use function can be used in automatic mode as well as with manual control functions.