The advantages of automated tugger train solutions

How you benefit from automated concepts

Trends like digital transformation and innovative processes such as lean production have turned production logistics into one of the fastest developing economic sectors. Automation solutions are playing an increasingly important role in meeting the requirements that are changing as a result. The key questions are: Is an automated tugger train worthwhile for my company? What are the benefits for me? Will the use of an automated tugger train let me reduce my costs for material transport and logistics?

Automation solutions have already successfully proven their worth in numerous pilot projects. They have also highlighted a whole range of clear benefits:

- Reduction of stock

- Increase in delivery frequencies

- Goods tracking in real time

- Minimisation of incorrect processes

- Space savings

- Compensation for staff shortages

- Financial benefits

- Less strain on employees

1. Reduction of stock

The highly cyclical, synchronised supply with automated tugger trains enables the efficient provision of small batch sizes and a significant reduction in stock in the production area.

2. Increase in delivery frequencies

Automated tugger trains enable efficient production. Deliveries to the necessary locations occur just in time or just in sequence. The material flow is integrated into the demand situation on the production machinery with precise supply and removal from the machines.

3. Goods tracking in real time

Using warehouse management software to track goods in real time makes it possible to achieve significant gains in quality and efficiency while avoiding search times and errors.

4. Minimisation of incorrect processes

Small errors are often all that it takes to disrupt an entire process and therefore the flow of goods. The use of automated tugger trains with corresponding monitoring software helps the operator minimise the error rate.

5. Space savings

Space for industrial areas is becoming increasingly tight, while the size of operations is increasing. The goal is to achieve space-saving intralogistics. Automated processes in the warehouse allow the necessary operating widths for industrial trucks to be minimised. Mobile handover stations enable flexible handling during loading and unloading processes – even in the tightest of spaces.

6. Compensation for staff shortages

Staff shortages have also been a significant problem in intralogistics for many years, since filling vacant positions with qualified staff is a huge challenge. Automated or autonomous tugger trains can help overcome this deficit.

7. Financial benefits

Manual activities are reduced. By reducing the maintenance costs and levels of damage to trucks and machinery, as well as minimising accidents involving personal injury, it is possible to achieve a dramatic reduction in costs. This increases the predictability of expenses while reducing provisions for unscheduled maintenance measures.

8. Less strain on employees

People play a key role in the use of conventional tugger trains, as muscle power is required to load and unload the trolleys on the frame. An automatic tugger train solution that replaces strenuous manual processes (such as loading and unloading) provides genuine added value for employees. Employee productivity is increased as inefficient travel times are eliminated. Instead, value-adding activities are performed by the operator.

“Automatically unemployed?”

The topic of automation is an ominous prospect for many employees. However, the implementation of an automated tugger train system is not at all associated with job cuts – on the contrary, it actually helps employees by taking over manual processes and counteracting staff shortages in other areas.

Requirements analysis

Our offer for the joint preparation of the concept and requirements specification

We answer the following question together with you: What potential for automation can be uncovered in your warehouse and production logistics – and what does your automation system ultimately have to achieve?

Result: an individual requirements specification based on your needs, which you can use for your invitation to tender. The requirements specification is the technical basis for your automation concept.

The close connection between production and logistics, the constantly increasing staff shortage, the demand for flexible production processes and digital production and logistics has led to a boom in demand for driverless transport trucks in the past few years. Logistics is the cornerstone for ensuring smooth operations in production plants: the quick and reliable delivery of the required material to the relevant stage in the process chain allows time and the associated costs to be effectively minimised.

Here, the automation of the processes is key. Tugger train solutions, especially if they are automated, ensure high process efficiency and a reliable flow of goods. Planning for a tugger train system that meets your specific needs requires expertise in this field, as a range of factors need to be considered.

Return on investment (ROI)

The return on investment must be extensively reviewed to make sure that the system will be a long-term financial success in relation to the amount invested.

Shift use

Does your company work in a multi-shift operation, where staff costs make up a significant share of the overall costs? The use of an automated tugger train concept can significantly reduce costs, particularly in three-shift operation.

Personnel situation

The use of an automated or autonomous tugger train solution can compensate for an existing staff shortage. For instance, if you do not have enough drivers, a driverless transport system can be a good long-term solution.

The framework conditions play an important role when looking to successfully implement an automated tugger train solution.

An automated tugger train guarantees a continuous supply without delivery errors as well as reliable and predictable supply times.

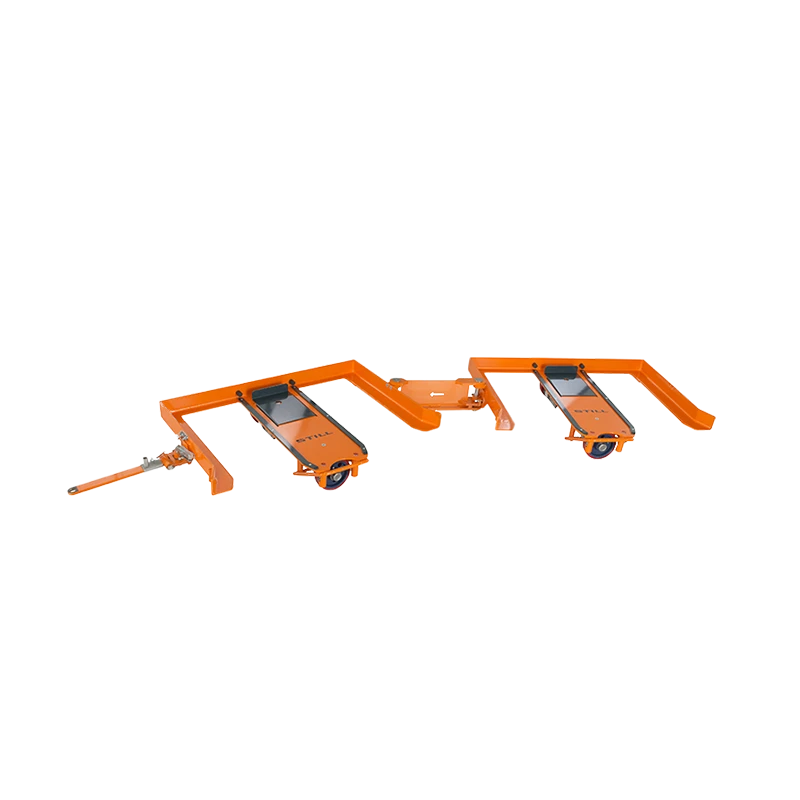

A rise in the level of automation is accompanied by a rise in the complexity of the requirements relating to the specific framework conditions. In particular, load handling has specific space requirements, especially with regard to the approach to the loading area. The complexity of process know-how and definition also rise in proportion to the increase in the level of automation. A coherent infrastructure, the availability of the necessary data (e.g. "Where are my goods currently located? When do they have to be transported and to which location?") and the associated flow of information are key criteria for the flawless operation of an automated tugger train concept. The following factors must be taken into account when using driverless transport trucks:

- ambient conditions (layout, available space, temperature, humidity etc.)

- quality and loading of carriers (weight, size)

- quality of the floor (wheel load, flatness, transitions, gradients, electrical resistance)

Questions to be answered:

- Do you have a warehouse management system?

- What is the situation in terms of the data availability on requirements, stock and consumption?

- Is your company as a whole willing to change and prepared to restructure its processes?

How flexible or rigid is an automated tugger train concept – and how future-proof is it?

Automation solutions in logistics are not a fleeting trend. They show the direction of future processes and successes. The different levels of automation are easy to scale. A route that has been automated once can be adapted, expanded and even combined with other automated solutions without a great deal of time and effort.

Automated tugger trains are primarily used by bulk manufacturers, assembly lines in series production, port and hospital logistics and in the recycling and retail sectors.

Typical applications include areas where long distances have to be covered in conventional long-distance transport without a driver, as well as where heavy loads are involved in the production supply route. The automotive sector is a clear forerunner in the use of automated tugger train systems, although a cross-industry trend is emerging.

Driverless transport systems (DTS) in general are predominantly used in the automotive sector, in e-commerce, production, the food industry, the aviation industry, health care, logistics and retail.

In summary: A cross-industry trend towards the use of automated tugger trains is emerging. Automation in intralogistics is a topic that is gaining momentum and, particularly in light of the booming economy, is the ideal solution for optimising processes. Automated tugger train concepts will play an increasingly important role in the future. The benefits of an automated tugger train solution are clear, from the minimisation of the process error rate through to the reduction of the physical strain on employees all the way up to the long-term relative reduction in costs.

We use our expertise to help you analyse your processes and identify automation potentials in order to set your company up for the future.

Following your request, we would be pleased to send you a free download of our white paper as an introduction to automated tugger trains.

Arrange a callback

Glossary

Master controller

The master controller controls all of the trucks operating in the system. It helps the operator continuously optimise the operation. It connects a general host system, such as a warehouse control system (WCS) or a warehouse management system (WMS), and the deployed trucks.

Tugger train

Tugger trains are a means of transport for ground-level material transport. They are generally made up of a towing truck and one or more trailers, on which carriers are placed. Both the driving and load handling can be carried out either manually or partly or fully automatically.

Driverless transport systems

Driverless transport systems (DTS) are defined as follows according to VDI Guideline 2510: They consist of various components that have to work together in a precisely controlled and coordinated manner. These include a master controller, equipment for detecting and recording the location and position of the transport trucks, equipment for transmitting data to and from the trucks in the DTS, infrastructure and peripheral equipment (e.g. charging stations).

Dual use

Driverless transport systems with a dual-use function can be used in automatic mode as well as with manual control functions.